views

Applying the Pipe Joint Compound

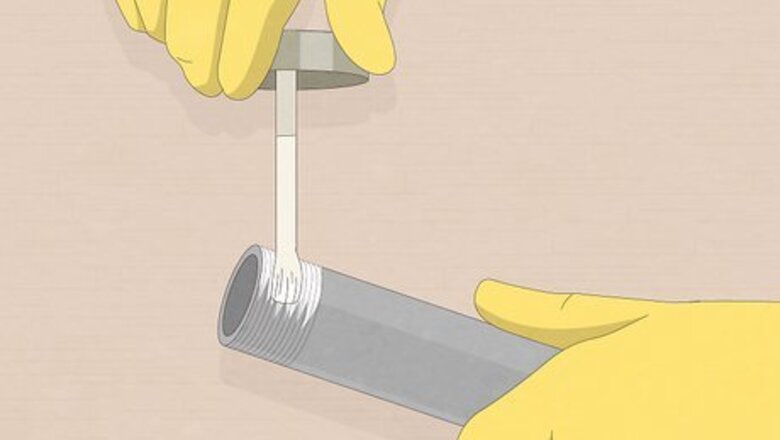

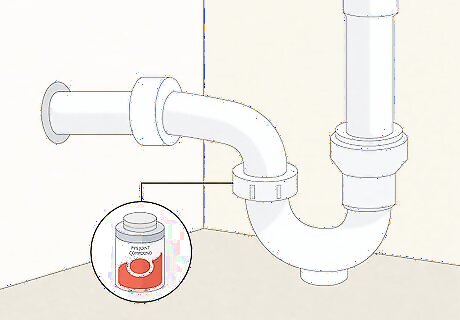

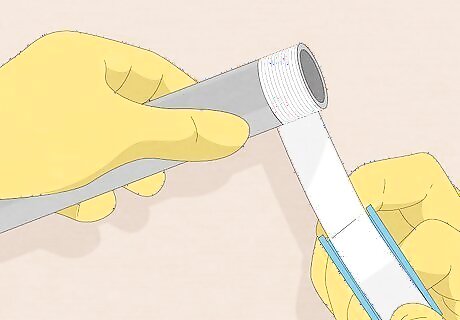

Brush the pipe dope onto the pipe or fitting. Unscrew and remove the lid from the bottle of sealant. Most products will include a small applicator brush on the underside of the cap. Use this applicator to smear the liquid sealant liberally onto the threads of the male pipe fitting. Make sure the pipes you're sealing are clean and dry prior to applying pipe dope. A small disposable brush or spatula can also be used if the pipe dope you picked up doesn't come with its own applicator.

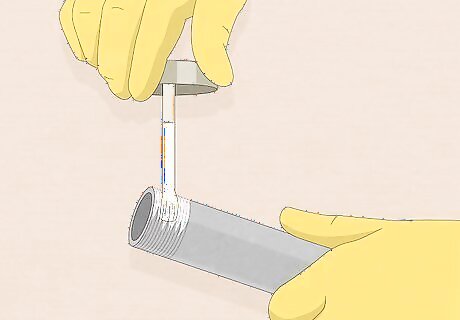

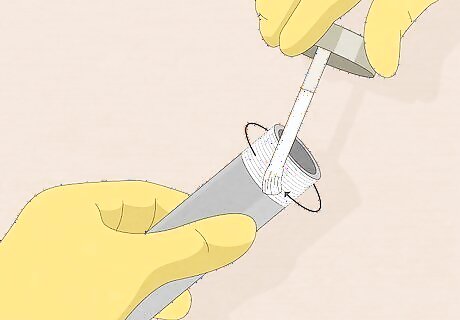

Spread the sealant in the opposite direction. Turn the pipe segment and go over the pipe dope once again, this time across the path of the threads. This will help fill in the threads and promote a stronger, longer-lasting seal. Reapply the sealant as needed to achieve full coverage. By the time you're finished, you should barely be able to see the threads at all. Be sure to only spread the sealant onto the threaded section of the male pipe segment, not on the female threads or any other part of the pipe. If you're fitting pipes together for a high-pressure application, you can use wicking to ensure water-tightness. Wrap string around the threads after applying the joint compound.

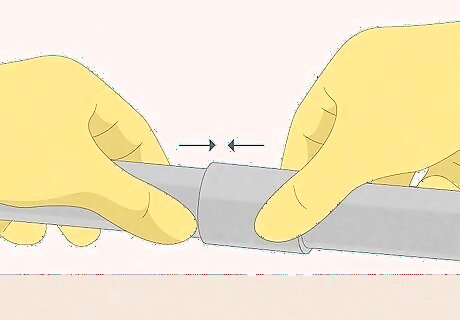

Fit the components together. Slide the male pipe segment into the opening of the female segment or fitting. Screw the male segment into place until it stops turning. If necessary, use an adjustable wrench to finish tightening the pipe. One additional benefit of using pipe joint sealant over other types of sealants is that it also serves as lubrication, allowing you to insert the male segment much deeper into the female segment or fitting. Liquid pipe sealants don't harden, which allows you to easily separate the pipes later on rather than having to cut and reinstall them. EXPERT TIP David Balkan David Balkan Professional Plumber David Balkan is a Professional Plumber, CEO of Balkan Sewer and Water Main Service, and President of Balkan Sewer and Drain Cleaning. As a hands-on owner of these companies for over 40 years, David is knowledgeable about water service lines, sewers, and drain line issues. David is a Committee Chairman of the Master Plumbers Council and has sat on the Executive Committee of the Sub Surface Plumbers Association of New York for over 30 years. His knowledge and solution-oriented approach contributed to Balkan Sewer and Water Main Service being the largest and most trusted service in New York City and the recipient of the 2017 Angie’s List Super Service Award. David Balkan David Balkan Professional Plumber Coat male threads with sealant. When joining pipes, only put pipe joint compound right on the exposed male threads themselves. For DIYers without pro supplies, use a special plumbing compound with Teflon that will expand when wet to seal any leaks.

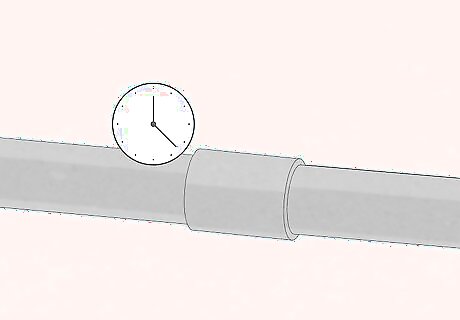

Give the sealant time to set up. Most pipe joint sealants will usually take between 5-15 minutes to begin solidifying on a standard 0.5–3 inches (1.3–7.6 cm) pipe. For larger pipes, however, or systems that will be subjected to high temperatures or continual vibrations, the sealant may require as long as 48 hours to set. Humid conditions may increase the initial set time by as much as 50%. Once the sealant has set, it will continue to cure for several days, or up to 2 weeks, for pipes 12–15 inches (30–38 cm) or larger. Many pipe joint sealants never fully harden—they'll remain slightly gummy in order to expand and contract within the pipe. Hold off on restoring water or gas flow to the pipes until the sealant has had ample time to form a secure seal.

Working with Pipe Joint Compound

Choose the right sealant for your project. The majority of pipe joint sealants are approved for use on a variety of plumbing materials, including various types of metal and plastic. However, this isn't always the case. Read the packaging of a product carefully before you buy it to confirm that it suits your needs. Using an inappropriate sealant could lead to serious leaks and other plumbing issues. It's important to pick up the right amount of sealant as well as the right kind. Pipe joint sealants come in sizes ranging from 1–32 fluid ounces (30–946 ml) canisters. To avoid inconvenient interruptions, make sure you've got enough to see your project through. For homeowners, a sealant made with Teflon can be helpful. Teflon expands when it gets wet, which can help seal leaks.

Wear gloves to keep your hands clean. It's a good idea to stay covered up with a pair of thick work gloves while working with liquid sealants. Pipe dope is a slippery, sometimes tacky substance that can be difficult to wash off once it's in place. There's a lot of potential to make a mess should it come into contact with your bare skin or surrounding work area. Rubber gloves will make an acceptable substitute if you don't have a dedicated set of work gloves. Should you happen to get any sealant on your skin, stop what you're doing and wash the affected area with soap and warm water.

Work in a well-ventilated area. Liquid pipe sealants set faster and more effectively in dry conditions. Like other similar adhesives, they might also give off mild fumes. Open a window or turn on the overhead fan to get some air circulating throughout the room as you work. Exposure to chemical fumes may cause you to feel dizzy or lightheaded if you're working in a confined space.

Using Pipe Joint Compound Correctly

Use a pipe joint sealant for major plumbing projects. Because it can be used on both metal and plastic components, there will rarely be a need to use anything else for home plumbing jobs. The fact that it stays gooey also means that it's easier to disassemble pipes later on without damaging them, unlike hard-curing compounds. Pipe joint sealant can be found at all major hardware stores and home improvement centers. Liquid sealants tend to be inexpensive, are easy to work with and don't require any other tools or substances to apply, making them a more practical option than complex multi-part sealants.

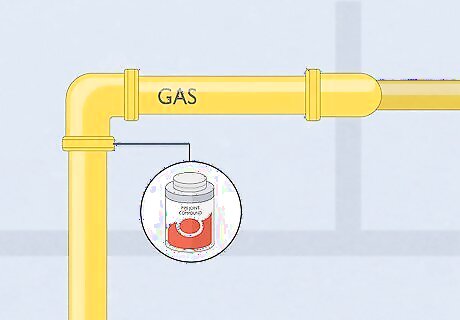

Seal gas lines. In addition to traditional plumbing projects, liquid pipe sealants are useful way to safeguard against gas leaks. They can be applied in exactly the same fashion, and in most cases the seal they provide is airtight as well as watertight. Read the packaging carefully to make sure the pipe joint sealant you're buying has been approved for use on the gas lines and for the specific type of gas you have (natural gas or propane, for example). You should test your home or business for gas leaks regularly, even if you're confident in your pipes' seal. You can do this by putting soapy water in a spray bottle and spraying the fittings. If you see lots of bubbles, you have a leak.

Stick to low temperature systems. While pipe dope forms a strong seal under normal conditions, intense heat can cause the sealant to shrink and crack. Eventually, this can lead to unexpected leaks. For water heaters, steam valves and other high-heat applications, you'll be better off using an anaerobic resin compound or bonding cement instead. Be prepared to reseal or replace high-temperature plumbing systems every few years.

Double up on sealants in high-stress areas. Pipes that experience a lot of rattling, vibration, or physical handling can be treated with a combination of sealants. The most common pairing is Teflon tape and pipe joint sealant. To use these two solutions together, first wrap the threaded male pipe segment with the Teflon tape per the product instructions. Finish with a coating of liquid sealant. The addition of an extra sealant layer will fill any remaining gaps within the pipe threads, resulting in a much more resilient seal.

Comments

0 comment