views

Removing the Screw

Choose a rubber band that is wider than the screw. It has to cover the opening in the screw head. In most cases, get a single, thick rubber band to try the screw trick. They are available in many places, including online and at office supply stores. Compare the rubber band to the width of the screw head to make sure it’s big enough to be effective. If the rubber band is too small, it will fail to fill the space in the opening. You won’t be able to get a good grip on the screw threads with your screwdriver. If you don’t have a rubber band available, try using steel wool or the green, abrasive side of a sponge.

Position the rubber band over the stripped screw. Press part of the rubber band flat against the screw head. Hold it firmly in place with one hand. Make sure you have a good grip on it and are able to keep it firmly against the metal for a few seconds. If you need to, reposition the item with the screw so that you have easier access to it. The entire rubber band doesn’t have to be over the screw. If the band is whole, move the excess aside. You may find the removal process a little easier if the band has broken open. For example, if the screw is in a board, try putting the board in a vise. Use the vise to keep the board still while you attempt to remove the screw.

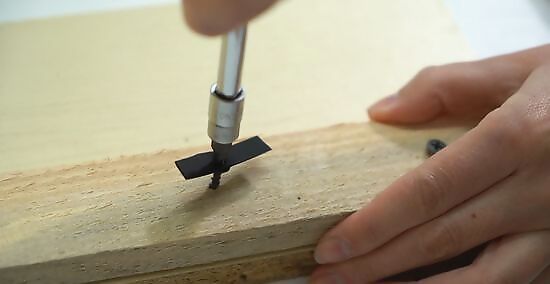

Push the screwdriver into the rubber band and screw head. Make sure the rubber band goes inside the opening on the screw head. It molds with the screw threads, creating leverage for the screwdriver. Hold the screwdriver steady to keep the rubber band firmly in place. If it falls out, remove the screwdriver and put it back in place. Press down with a firm amount of pressure so that the rubber band fits against the threads. However, be careful to avoid breaking through the rubber band.

Turn the screwdriver counterclockwise to remove the screw. Work slowly, since the screw will still be difficult to turn. While maintaining firm pressure on the rubber band, gradually turn it. You should feel the screw begin to turn and come loose. Reposition the rubber band if necessary and continue working until you are able to remove the screw. The screwdriver may penetrate the rubber band at some point, especially if you’re using an electric screwdriver. Move the rubber band over so you can use an unbroken section of it. Even if you do everything right, you may not succeed at removing the screw this way. When this happens, try using other tools, such as a drill.

Handling a Stuck Screw

Use a hammer to drive the screwdriver deeper into the screw. Place the rubber band over the screw as usual, followed by the screwdriver. Then, tap the back end of the screwdriver a few times to wedge it in place. Sometimes, doing this enables the screwdriver to get a better grip on the screw threads. Test it by attempting to slowly turn the screw counterclockwise. This could potentially break through the rubber band. If you notice that happening, remove the rubber band and try using the screwdriver without it.

Drill through the screw if you can’t get a good grip on it. Use a power drill fit with a ⁄8 in (0.32 cm) drill bit. Position it in the center of the screw head, then begin drilling straight down. Stop when you reach the bottom part of the screw head. Then, try removing the screw with a screwdriver and rubber band again. Make sure you’re using a drill bit designed to work on metal, such as a titanium bit. You can potentially damage the screw by drilling it. Work slowly and drill straight down through it, taking care not to drill too deeply.

Cut into the screw with a rotary tool if it is still stuck. An oscillating tool, such as a Dremel, can cut into metal with precision. Plug a metal-cutting disk into the end of it, then lower it onto the screw head. Use the edge of the disk to deepen the screwdriver slot. Then, insert the rubber band and screwdriver to try and remove the screw. Gradually deepen the lot on the screw, but keep it roughly the same size as the screwdriver you are using. When done correctly, it allows the screwdriver to get a better grip on the threads.

Comments

0 comment