views

X

Research source

This type of roofing is available in an array of colors, textures, and styles which can suit anyone's aesthetic preferences. Install your own metal roofing to increase efficiency and add style to your home while saving money.

Readying Your Roof

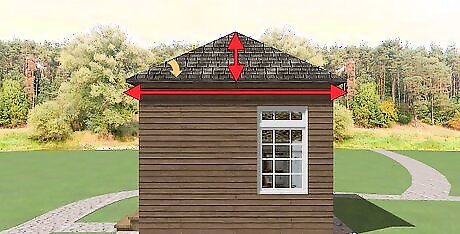

Measure the length, width, and rise of one section your roof. Before you can begin to update your roof, you will have to get an accurate measurement and order your materials. First, measure the length and width of one section of the roof, then measure the distance the roof rises from the lowest point to the highest point. Always try to measure from the ground first in order to keep yourself safe. If you must climb onto the roof to measure the space, be sure to use caution.

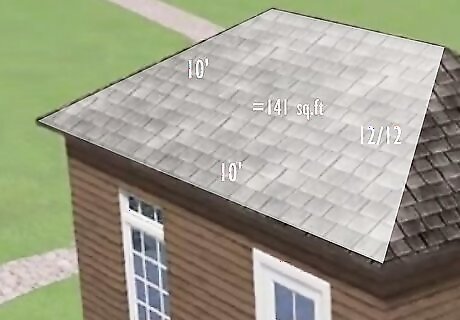

Calculate the slope factor of your roof. The slope is given as rise-over-run, meaning the distance up (rise) divided by the distance across (run). This measurement will typically be a measurement across 12 inches (30.5 cm) and be something like 4/12 or 8/12. Convert this to the equivalent slope factor using the formula √(rise + run) ÷ run. First square the rise by multiplying it by itself, then square the run by multiplying it by itself and add the results. Next, take the square root of that total and divide by the run to arrive at the slope factor.

Use the slope factor to determine the area of the section. Take your area measurement (length x width) and multiply this by the slope factor. This means the slope factor form is: length x width x slope factor. This will give you the number of square feet that need to be covered. For example, if your roof measures 10 feet (3.0 m) x 10 feet (3.0 m) and the slope of the roof is 12/12 (giving a slope factor of √(12x12 + 12x12)÷12 converts to 1.414 in decimal form), you would multiply 10 x 10 x 1.414 to get the total of 141 square feet of roofing.

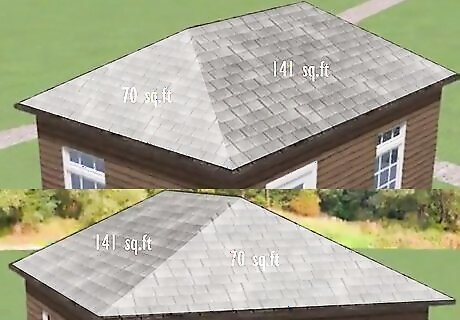

Find the square footage by adding up the total for each section. Repeat the process on each section of the roof. Then, add each number together to find out how much metal roofing you need to order. Purchase extra roofing to allow for a minimum of 10% waste.

Get your materials. You will most likely have to order the roofing metal in the amount and color specific to your house. You will also need a large garbage can, a jigsaw or power metal shear, a staple gun, a drill, and assorted drill bits, 1¼ inch roofing nails, metal roofing screws, and self-drilling, self-sealing wood screws.

Prepare a work site. In order to make your installation as easy as possible, it is important to have a well-organized work area. You will need a large bin for trash (old roofing and debris), a place for tools, and your scaffolding or ladder set up. Make sure that if you are using electric tools that none of the cords are in the way. Store the material in a readily accessible area, protected from the weather. The panels are weather-proof but staining can occur if left open to moisture

Remove the old roofing. Although you can install corrugated metal roofing over shingles, for the best foundation, it is recommended that all the old roofing be removed. Work at a comfortable, steady pace, trying not to rip up or carry off too much old roofing at once. Start at the highest point and the furthest point from the trash container and take off all the old shingles, flashing, vents, and boots. Replace all these with the new metal roofing. If you come across any large nails that are sticking out, either remove them and put them in your debris container or hammer them flush so that they aren’t a danger to anyone working. If you need to reposition your gutters, do so at this point. Always remove the old roofing on a day (or set of days) when the weather is expected to be dry and sunny, as you don’t want to let any rain or moisture into your building.

Repair any damage. With the old materials removed, the bare bones of the roof frame or plywood sheathing will be exposed. If there is any damage to the sheathing (the wood under the shingles), insulation, or ventilation, fix it now.

Add your insulation layer. This helps to block moisture from getting trapped between the metal roof and the sheathing. Use roofing felt to cover the entirety of the roof and secure it with a staple gun or nails, then cover it with a breathable membrane.

Installing Your Roofing

Install the edging. The edging, or eave flashing, consists of metal strips that are used to cover the perimeter of the roof. Use your 1 ⁄4 in (3.2 cm) nails to secure the flashing to the subroof. It should overlap the edge of the gutter (if you have them).

Add the metal panels. Always begin working at the point with the longest peak-to-eave distance. Take your first sheet of metal and place it on the roof so that it overhangs the edge at least ⁄4 in (1.9 cm). Take care the first piece is aligned precisely perpendicular (square) to the edge. Use your neoprene washer head screws to secure the metal to the sheathing. Space the screws about 12 in (30 cm) apart down the entire piece of metal. Make sure that the screws are all aligned evenly, as you will be able to see them from the ground if they are exposed-fastener metal plates. For exposed fasteners, avoid over-tightening the fastener. Each fastener has a durable rubber grommet that seals the roof from the weather. Tighten the fastener just enough to seal the site. If you over-tighten and the grommet is displaced, remove and replace. Continue installing the metal panels, making sure that the edges overlap at least 1 in (2.5 cm), or as required, with the adjacent panel. Do this until the entire roof is covered. If you feel the need for sealants, lay a bead of 100% silicone or adhesive silicone before laying the sheet down and make sure the bead is towards the edge of the bottom sheet. This will allow the silicone to squeeze out towards the edges, making it a more tight seal.

Add the flashing. This is the metal trim similar to the eave flashing, except that it is placed over joints in the roof where different sections meet. This should be used in valleys (points where 2 sections less than 140 degrees meet) and as end caps over the tops of 2 sides that meet. Be sure to cut this metal at the correct angle before installing it. The flashing can be bent into a ‘V’ shape to fit over the top of a section (ridge) of a roof, if necessary. Depending on how wide the flashing you’re using is, you will either have to use 1 or 2 rows of screws.

Finish your roof. Make sure that you’ve completely covered the entire roof with the metal, that all edges are smooth and finished, and that there are no loose pieces. Clean up all remaining metal, nails, and screws and enjoy your new roof!.

Comments

0 comment