views

Organizing the Project

Select a sturdy uncut mirror for your project. If you want to custom cut a mirror, almost any piece will do – you can purchase uncut mirror glass from a hardware store or repurpose something you already have. Avoid cutting mirrors that are already severely chipped or cracked in multiple places. A mirror in bad condition may not be able to withstand the cutting process and shatter while you’re working with it. If you’re looking for another source to buy uncut mirror, look for specialty shops that deal specifically in mirror and glass. It may be helpful to purchase a few pieces of inexpensive mirror to practice on. Try single-strength window glass, since it is easier to cut and usually the least expensive.

Clean and dry the mirror thoroughly. Use glass cleaner or rubbing alcohol and a microfiber cloth to wipe down the mirror’s surface. Clean it thoroughly – you need it to be as spotless as possible, because even the slightest speck of dirt or dust can cause interruptions during the scoring process. This may result in the glass chipping or breaking. Use another microfiber cloth to wipe the surface down once more to ensure the mirror is completely dry before you begin.

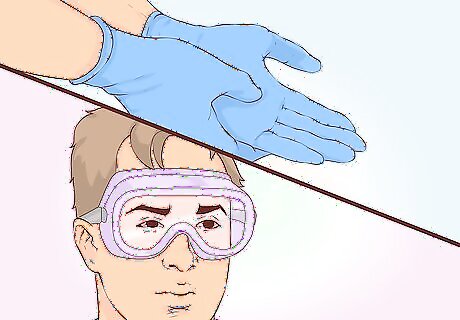

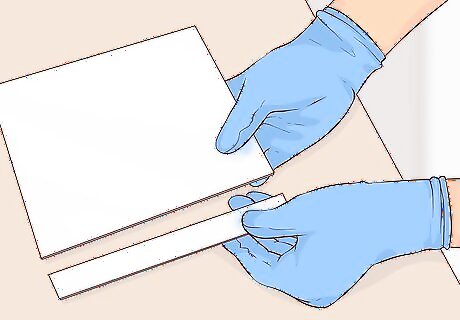

Wear protective gear. During the scoring and breaking process, tiny shards of glass will be discharged. These could potentially get into your eyes. It’s very important to wear some kind of eye protection or safety goggles when you’re working with glass. Don’t rub or touch your eye area while you’re working. Wear protective gloves, especially when handling freshly cut glass – the edges will be very sharp. Avoid wearing open-toed shoes or sandals. If you end up with a glass splinter, try to remove it by placing a sticky piece of tape over it and then whipping it off quickly. If that doesn’t work, use tweezers.

Scoring the Mirror

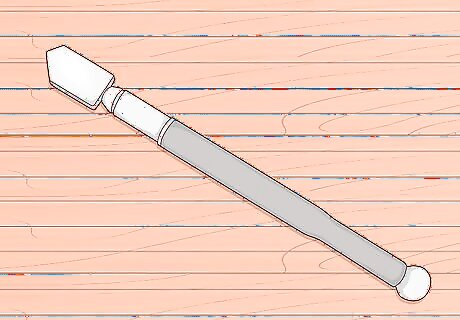

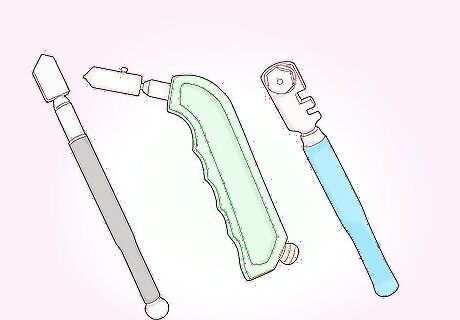

Choose a quality glass scoring tool that meets your needs. Most scoring tools feature a carbide cutting wheel on the end, which scratches the glass, and it is attached to some kind of handle. These tools are sometimes referred to as wheel-cutters. The wheels come in different diameters, with the smallest ones being best for detailed work. Wheel-cutters are relatively inexpensive, so it’s worth it to get one of higher quality. Look for scoring tools that have a sturdy design and a true carbide wheel. The cheaper tools can cost as little as five dollars. Those of higher quality are usually closer to twenty. You can get glass scoring tools at craft shops and hardware stores. Hardware stores usually carry the more expensive, sturdier models.

Select a scoring tool that can best handle your design. Some scoring tools are meant to score straight lines and others will score curved lines. Select your tool according to the design you have in mind for your mirror. The different handle shapes offer a variety grips. Choose what’s most comfortable for you to hold. If you have a very small job to do, look for a steel-wheel cutter. They work as well as the carbide wheels, and are even cheaper. If you are looking to cut a lot of mirror, invest in the self-oiling mirror cutter. It can last longer than other cutters, and is usually easier to use. EXPERT TIP Bicycle Glass Bicycle Glass Glassblowing Experts Bicycle Glass Co. was founded in 2016 by David Royce and Michael Boyd, two professional glass experts. Bicycle Glass is primarily a lighting company, committed to quality, sustainability, and affordability. All Bicycle Glass products are made of high-quality, recycled glass and are hand-blown by a dedicated team of artisans. The studio is committed to reducing its carbon footprint by conserving energy in all of its production. Using renewable wind energy to offset all electricity usage, the studio is actively working toward the goal of carbon neutrality. Bicycle Glass believes that high-quality, handmade glass products should be within reach for everyone. Bicycle Glass Bicycle Glass Glassblowing Experts There are various ways to cut glass, but the easiest way is to use a glass cutter. You can find commercial glass cutters suitable for DIY crafts that work well with flat plate glass. Use a circular glass cutter to cut circular shapes out of glass plates. It scores lines in the shape of a circle, making it easier to break the glass along the score line and tap away the unwanted edges. The method you choose to cut glass depends on the available tools and what you intend to do with it.

Measure and mark your cut lines with a straight edge. To make a clean break, your measurements and cut lines need to be as precise as possible. Use a straight edge to mark your cut lines on the mirror’s surface. Mark the cut line with a sharpie or white crayon. The cut line will be your guide so that you can accurately run the scoring tool over it in one continuous motion. The cleanest break lines will be created when you score with one continuous motion of the tool. Always mark your score lines starting at one edge of the glass and ending at the other.

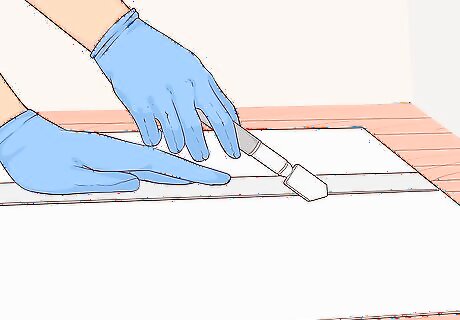

Place your scoring tool at the beginning of your first cut line. Put your mirror on a hard, flat surface that is free of debris. Hold the scoring tool vertically in your hand and line the wheel up at the beginning of your first cut line. Place the straight edge right beside the line so you can score along right next to it. This will give you the straightest, most accurate results. You can run the scoring tool along the line toward you or away from you. Try both ways to find out which you feel most comfortable with. If you’re concerned that your straight edge might wiggle around while you’re scoring, try using a simple clamp to hold it firmly in place.

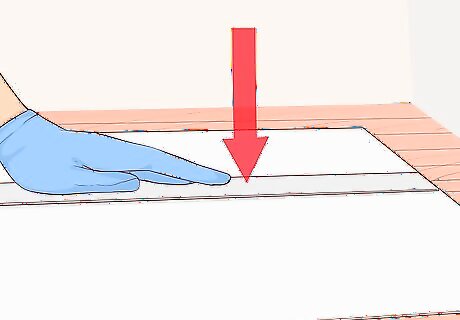

Apply a slight downward pressure while rolling the tool along the line. With most mirrors, you should hear a screeching sound if you are doing it correctly. If you don't hear that sound, you aren't pressing down hard enough. If you press too hard, you will notice tiny chips collecting around the score. These may get under your wheel and damage or dull your cutter, so brush them away immediately if you see them. Try to apply an equal amount of pressure for the duration of the score. Avoid lifting your tool up during the process so that you can score the line in one continuous motion.

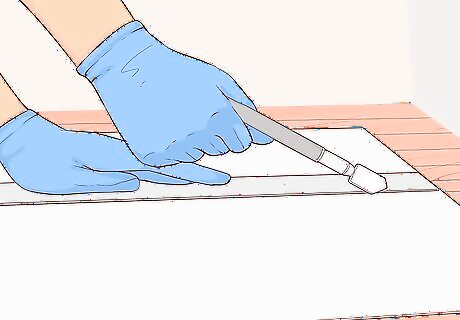

Score the remaining cut lines. Continue scoring the mirror until you have completely outlined your intended design. Stop every other score or so to brush away glass shards that have collected on the mirror’s surface and on your work surface. Leaving glass chips around while you’re in the midst of scoring can interrupt the accuracy of your cut lines and damage the carbide wheel on your scoring tool. For best results, try to keep your work space as debris-free as possible throughout the process.

Breaking the Mirror

Use your hands to break a small mirror down the scored line. There are a number of ways to cleanly break the mirror. One of the easiest ways is with your hands, although it’s not always the most ideal, especially if you are working with a very large piece of mirror. If the mirror is small enough for you to hold, firmly grasp it in both hands and place one thumb on each side of the first score line. Press down with both thumbs simultaneously, taking care to do so with equal pressure. Quickly make a snapping motion with your wrists and the mirror should break crisply along the score line. EXPERT TIP Douglass Brown Douglass Brown Glassblowing Expert Douglass Brown is a Glassblowing Expert based in Half Moon Bay, California. He has over 25 years of experience as a glass artist, and is the owner and operator of 2 glass blowing studios in the San Francisco Bay Area, Half Moon Bay Art Glass and Mare Island Art Glass. Douglass believes in sharing hot glass experiences with anyone who wants to learn about the processes of blowing and sculpting glass. When not teaching, Douglass creates glass art that is a mix of his takes on nature and functional glassware. He has also created the Glass Troubadours, which is a mobile glass blowing studio that hosts parties, events, and visits craft shows. Douglass Brown Douglass Brown Glassblowing Expert Protect yourself from injury. While breaking the glass it can shatter in ways you aren’t expecting. Wear protective gloves when handling cut glass. Industrial or gauntlet gloves provide better protection than disposable gloves.

Snap larger score lines by applying pressure on a flat surface. Place the mirror, scored-side down, on a soft and flat surface. Use your hands to press down on the unscored side, applying pressure along the score line. The glass should cleanly snap. You can also place the mirror on the edge of a flat surface, making sure to line up the score line with the edge. Use your hand to press down on the side of the glass that is hanging over the edge until you see the glass snap crisply.

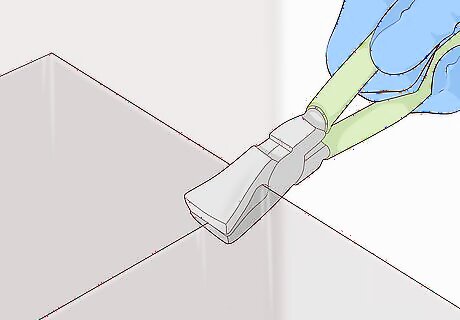

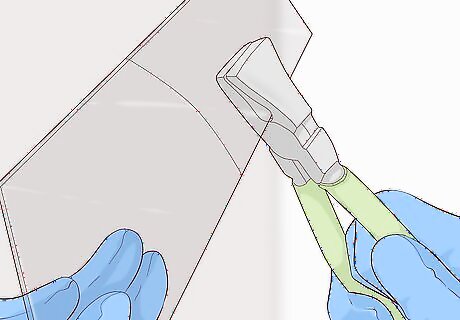

Break the glass along the score line with running pliers. If you feel uncomfortable breaking the mirror with your hands, or if the piece of glass is too large to do it that way, use running pliers. Place them so the bottom jaw touches the score on your mirror. The top jaw should touch the mirror about 1/2 inch (1.3 cm) on either side of the score line. Squeeze the pliers, which will cause them to separate, and the pressure will widen the score line. This widening will cause the score to crack along the rest of your line in a very controlled breaking pattern. If you’re breaking a long score line, you might want to apply the pliers gently at one end, until you hear a very faint clicking sound. Then turn the mirror around and do the same thing on the other end of the line. This will cleanly complete the break at the edges.

Use running pliers and a springy surface to break curved score lines. For scores that have multiple curves, turn the mirror upside down on a springy surface, such as a piece of foam or cardboard. If the curve isn't very dramatic, press down on the score line with your thumb, which will cause the break. However, running pliers are the best to use on curves and semi-circles. If you're cutting mirror with lots of curves, invest in running pliers and the breaking process will go much more smoothly.

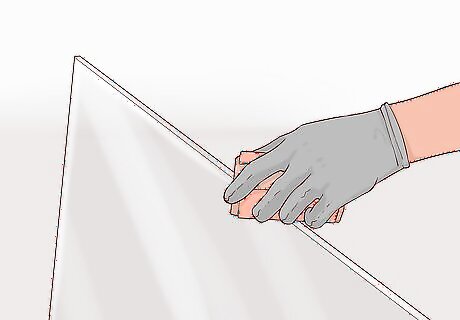

Sand and seal the edges of your newly cut mirror (optional). If you’re placing your mirror in a frame so that the raw edges won’t be visible, this is probably unnecessary (although you can still do it if you like). Sand down the edges with sandpaper, then apply mirror edge sealant or some other hermetic coating to the edges. You can find these materials at any hardware store. You can also use clear fingernail polish and get similar results.

Comments

0 comment