views

Removing a Lawn Mower Engine

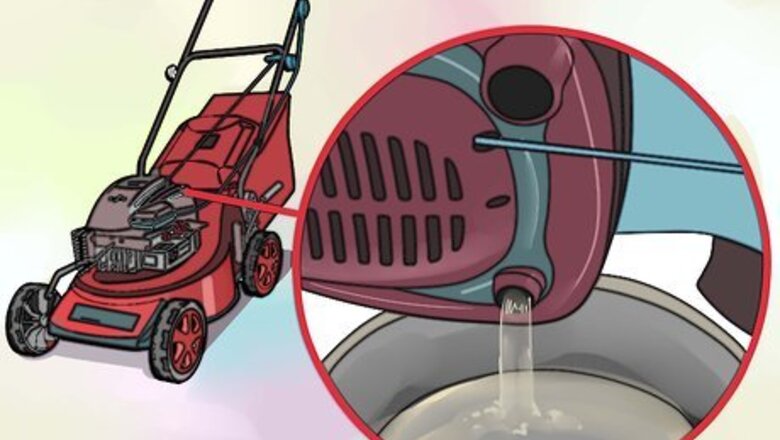

Drain the oil. Depending on the engine you are using, you may need to use a pair of pliers to disconnect the spark plug wire to remove the oil drain plug. Use a suitable receptacle to drain the oil into, and wipe any spills. It's best to drain the oil from an engine when it's slightly warm, as the heat allows for a faster flow than when cold.

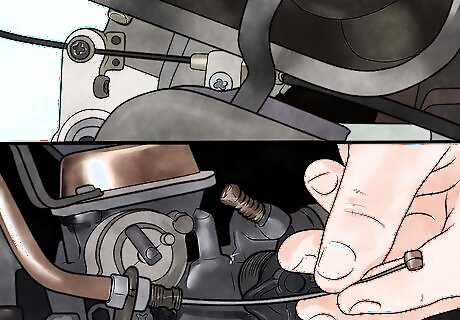

Drain the gas. Loosen the fuel hose clamp before you start draining your fuel. You can do so by tracing the route of the fuel hose from the engine to the base of the gas tank. Notice where the hose attaches to your lawn mowers carburetor. Using your pliers, squeeze the clamp loose and slide it upwards on the hose. Now you can detach the hose and drain your fuel into a bucket.

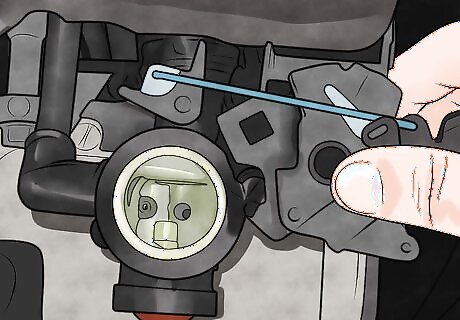

Locate the throttle linkage. You can usually find the throttle linkage beneath the carburetor. There will be a cable that should connect to the throttle, and by removing the screw that holds the cable in place, you can easily remove the throttle linkage.

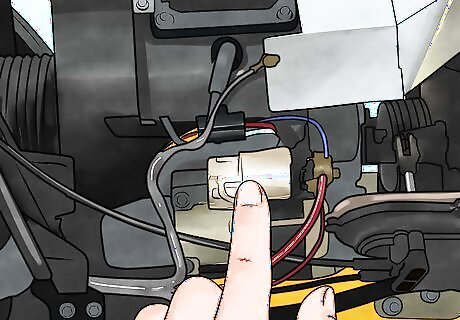

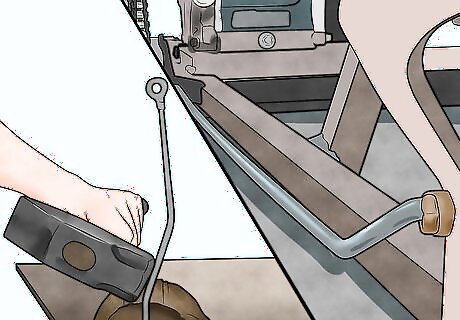

Find the starter. This part is on the side of the engine and will have the shape of a small can. Electric-start lawn mowers will have a red battery cabled attached. Use a wrench to unfasten the cable from the starter.

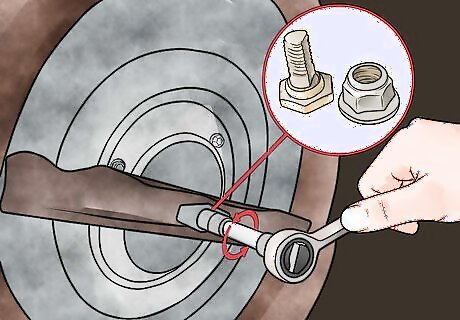

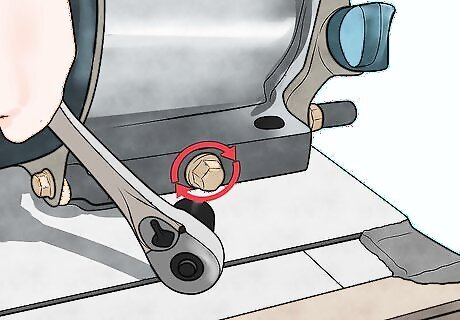

Remove necessary nuts and bolts. At the base of your mower engine is the mower house, which is where the engine is seated normally. Using your wrench on the bolt and another to hold still the nut below the mower house, unscrew the bolts holding your engine in place.

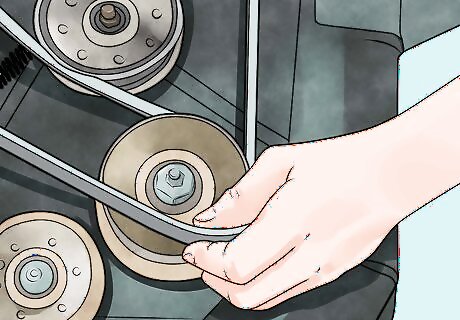

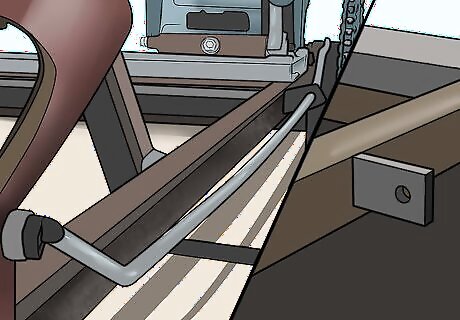

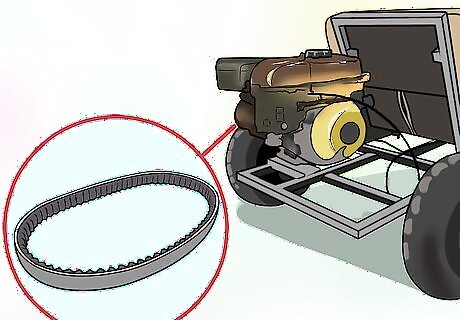

Take off the drive belt. You will find the drive belt on pulley on the crankshaft beneath the engine. Incline the engine slightly forward and pull the drive belt from its pulley.

Remove the engine. Taking the engine firmly with both hands, lift the engine from the mower house and place it carefully off to the side in a safe place.

Preparing to Install

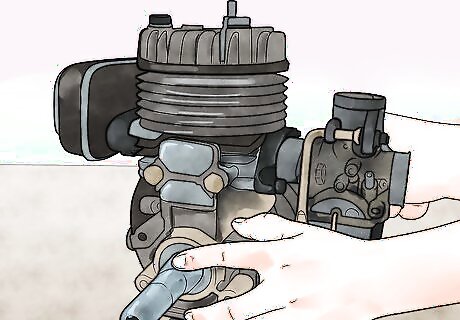

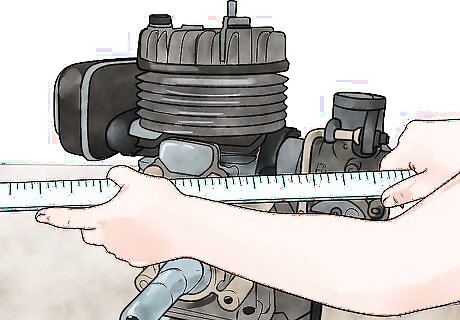

Measure the size of your engine. You will need a go-kart frame that is capable of housing the size and weight of your engine. Most 5 to 7 horsepower engines will fit a standard size kart. The vertical shaft engine you choose can be from a riding mower or a push mower, either will work for your go-kart. Larger engines in the 13 to 22 horsepower range, which you can find on riding mowers, may destroy the transmission or kart.

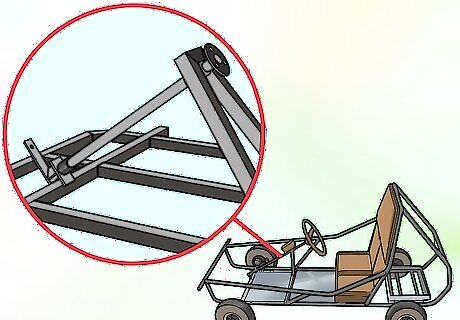

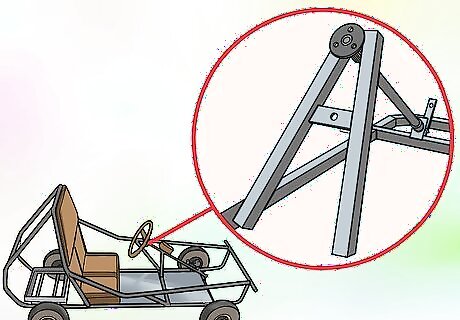

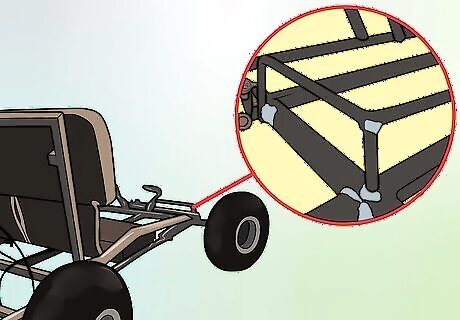

Pick a suitable go-kart frame. You will want one that can support both your vertical shaft engine and lawnmower gearbox comfortably. Your gearbox should will need to have non-trans axle set-up.

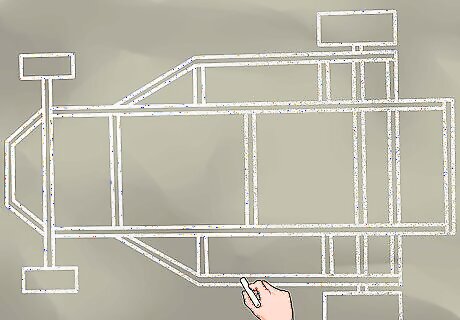

Draw out a true to size basic design of your frame with chalk. This will give you a better sense of the dimensions that will be comfortable for your frame. Most frames have a width that varies between 1/3 and 2/3's the wheelbase of your go-kart, with wider models giving better stability.

Assembling the Frame

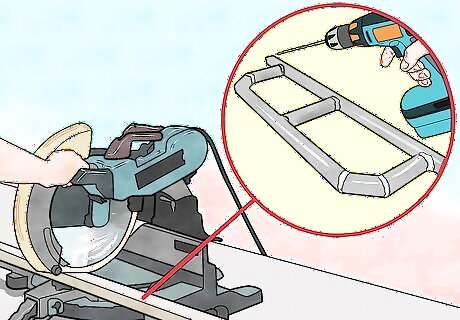

Cut bumper frame and drill holes for tube padding. You should round the edges of your bumper by connecting the vertical pieces that link to your frame and the horizontal piece parallel to the back piece of your frame with a short connector cut on a 22.5 degree angle. Drill holes for your tube padding into the back of your bumper. Drill 5/16" centered holes through your bumper padding at 1 1/8" from the padding end.

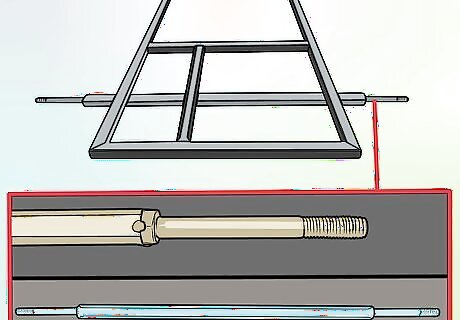

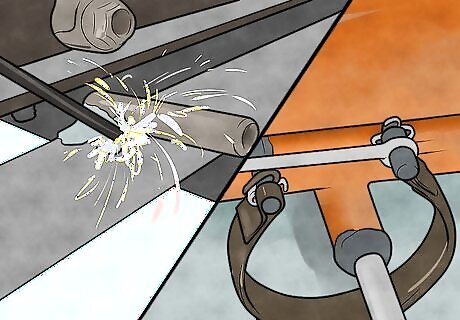

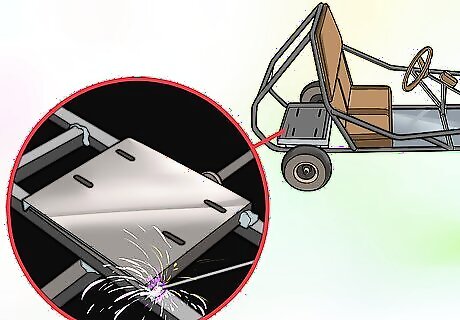

Install the axle. Cut a 1" x 1" section of square tubing and weld bolts to the ends. A 6" bolt will go on the driver's side of your kart, while a 4" bolt will be on the passenger side. Weld the axle underneath the base of the frame. Always use proper protective gear when welding. Failing to do so can result in significant harm to yourself.

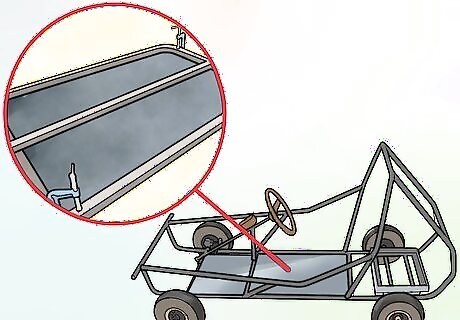

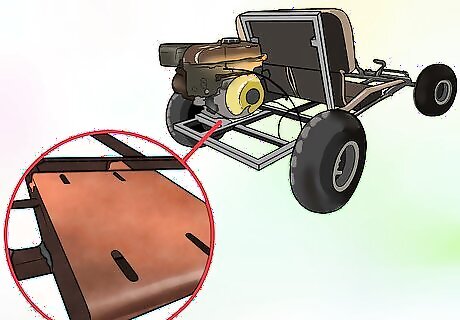

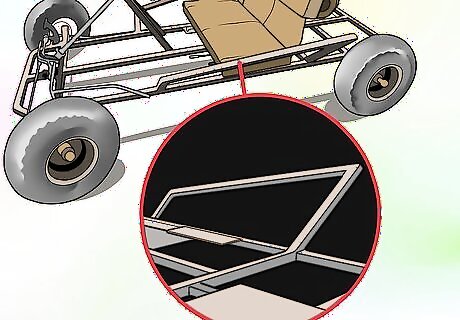

Put in a floor. A 16 gauge sheet metal piece should be sufficient for the floor of your kart. Using your plans from earlier, drill holes in the sheet for the fastening bolts for your seat.

Weld a brace for your seat. You should brace both outer sides of the go kart frame with flat, 3/16" gauge steel. This is where you will install the bench for your seat.

Assembling the Steering Column, Tabs, and Spindle Brackets

Cut and install you steering column. You should cut a section of 3/4" x 11 gauge tubing and weld it to your steering tabs. Insert an additional 1" spacer loosely by the shaft near the steering hoop, grinding the shaft slightly near the hoop if too tight. Drill a three hole pattern with the holes equidistant from the center of the washer at the end of your shaft.

Cut the steering hoop and kill switch brace. Make your cuts at a 39 degree angle for your hoop. At this time you should verify that all measurements for your steering assembly are correct for your kart and allow for a full range of motion. The hoop and shaft should be at a 90 degree angle to one another.

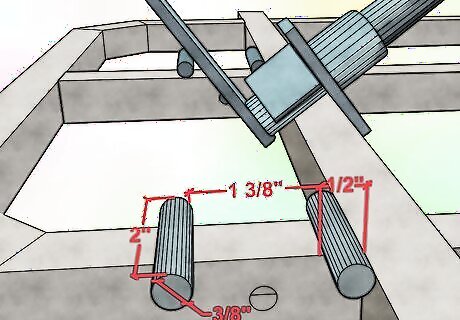

Add resting tabs for brake and throttle. These 2" long 3/8" diameter tabs keep your pedals in their resting and full forward positions. The closest tab to the center of the frame should be fixed a max of 1/2" after the crosswise piece your to which your steering column is attached. The second tab should be installed 1 3/8" after the first tab.

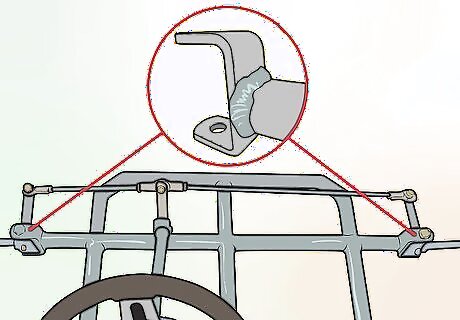

Attach spindle brackets. You will weld these to the front axle of your go-kart. The spindle should have a 1" clearance above the front axle.

Give yourself a foot rest. Use a 3/8" rod in a vise to bend it with a hammer into the shape of your passenger footrest if applicable. This will keep your feet from resting on tie rods.

Don't forget your brake band stud. This stud will serve as the pivot for your brake band. Weld a 3/8" round bar to the frame 1 1/2" after your axle.

Assembling Motor Mount, Brake Rod, and Accessories

Install your motor mount. Make sure your motor mount slots allow your engine to slide forward slightly, and then tack the mount into place. No dimensions are included here deliberately, as the size of your mount will change according to engine. The motor mount should be welded as the final step to building your kart. Your mount should be able to hold your lawn mower engine in the horizontal position.

Attach the throttle cable guide tab. About 4" away from the middle of the throttle pedal bolt hole, weld this tab to your kart on a 45 degree angle.

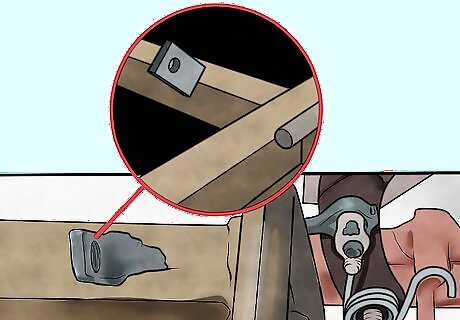

Put in the brake rod guide tab. Take your brake rod and insert it through the tab, bending it to adjust it to the brake band. Next, take the tab with the rod inserted and weld it to the kart.

Bend your brake rod into shape. Bend this 1/4" round rod so that it angles to meet your brake pedal assembly. Cut the length of your brake rod as needed, and weld eyelets to the rod with a return spring installed brake pedal.

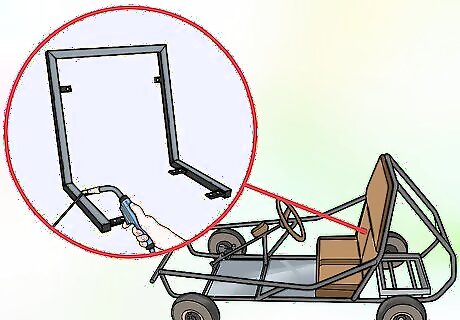

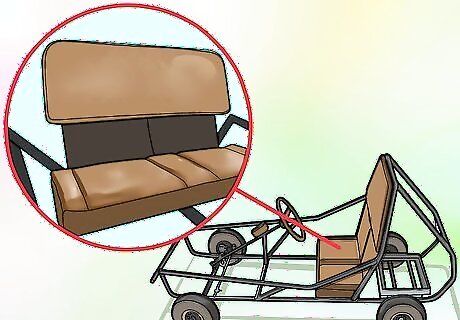

Give yourself a seat. Many go-kart kits do not bolt seats directly to the kart. If this is the case for you, use a simple frame and bolt this into the seat braces. Your seat should be cut at a 37.5 degree angle for a 105 degree incline for your backrest.

Choose your side rails. There are many different designs you can use, but the traditional side rail is formed of three pieces joined to form a rectangular rail with the side and back of the frame. Side rails are an optional addition for your go-kart.

Weld motor mount and attach accessory parts. Having finished with the body of your go-kart, you can now weld the mount to your frame. Upon completing your weld, you can add tires, seat padding, and all other necessary hardware to your vehicle.

Installing the Vertical Motor and Gearbox

Bolt down both motor and gearbox to the mount. The location of your motor is not as important as that of the gearbox. To properly install your gearbox, align it with the gear on the rear axle, and then bolt it into place.

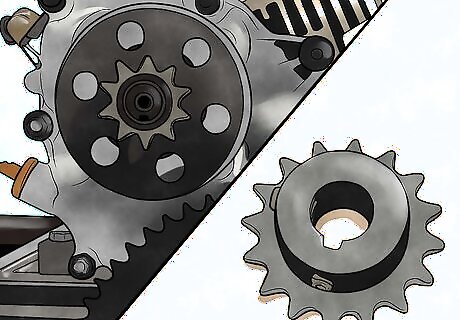

Change the sprocket size for the gearbox. A sprocket is a gear toothed wheel inside your gearbox that controls the gear ratio for your transmission, which is another name for the gearbox. Your target gear will be about 16 teeth.

Utilize, for clutching, the manual belt slip clutch from the lawnmower. One end of your clutch should be installed into the engine, with the side protruding a sprocket connecting to your gearbox. If you lack a manual belt slip clutch, you can buy a centrifugal force clutch from your local auto parts store and use that instead. The ratio between your motor and transmission should be 1 to 1.

Attach a throttle cable to throttle linkage on carburetor. Now you can clean off any residual oil from your kart, but do so with care. Always allow for sufficient time for the materials you are working on to cool, like the engine or solder, before using a cleaner.

Comments

0 comment