views

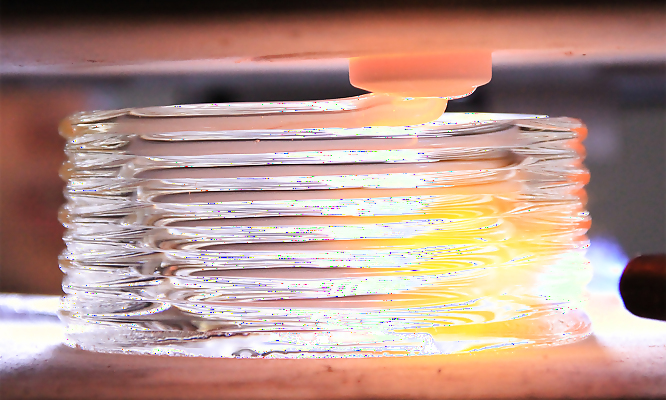

The first of its kind, optically transparent 3D-printed glass has been developed by researchers at MIT.

Eliminating the need for a solid core but coiling the foundation in a molten strand instead, the process diverges significantly from conventional glassmaking, which can include molding, forming, blowing, plating or sintering, say the researchers.

They're calling the process G3DP and they say it allows glassmakers to determine color, transparency and light transmission with the ultimate precision, opening up a range of possibilities.

The Kiln Cartridge -- the part of the 3D printing platform that's used to heat the glass -- gets as hot as 1,900 degrees F.

To read the paper on the project and watch a video: matter.media.mit.edu/environments/details/610

Comments

0 comment