views

Preparing Your Workspace and Wood

Put on protective clothing and work in a well-ventilated area. The staining products used to color the oak can stain your hands, so wear rubber gloves. Always wear a respirator mask to avoid breathing in chemical fumes as well as wood particles from any sanding you do. Additionally, keep fresh air circulating in the room. You can improve the room’s circulation by opening any doors and windows nearby. Make use of fans or work outside. Purchase a respirator mask from a general store or hardware store.

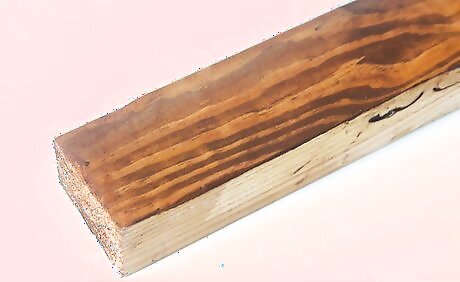

Sand the wood with 120-grit sandpaper. Select a medium-grit sandpaper, then look closely at the wood to find the direction of the grain. Work along the grain, lightly sanding to remove debris and prepare the oak for staining. Always move in the direction of the grain when sanding wood to ensure a smooth, uniform finish. The grain is the dark lines in the wood, and in red oak these lines are very easy to see.

Smooth out the wood with 220-grit sandpaper. Switch to a fine-grit sandpaper and go back over the wood. Lightly abrade the entire area you wish to stain. Blow off any wood shavings left over on the oak. You can use a cloth or vacuum to make sure all of the debris is off of the wood. Any debris left over can interfere with the stain.

Dyeing the Red Oak

Mix a wood dye in water. These dyes are give oak a consistent base color that improves the final stain. All you have to do is stir the dye powder into a glass jar filled with water according to the manufacturer’s instructions. Mix the dye powder in 50% more water than the label recommends, since this thins the dye and prevents the wood from absorbing too much color. For example, you might mix about ⁄2 cup (120 mL) of dye in 2 cups (470 mL) of hot water. Visit a home improvement store to find a variety of wood dye shades. For example, a honey amber dye works well on red oak, turning it a light brown color.

Mist the oak with water to improve dye absorption. Fill a spray bottle with room temperature water. Move the bottle along the wood as you spray water onto it. You want to lightly moisten it, not saturate it. The water fills the oak’s pores, causing it to dye more evenly. You can also use a sponge to moisten the wood. While you can stain dry wood, this may lead to dark patches and streaks in the stain.

Spray the dye onto the wood. Empty out the spray bottle, then load the thinned dye into it. Bring the nozzle close to the oak as you begin misting the dye onto it. Slowly move the bottle along the oak to cover it in a light, even layer of dye. You can also use clean rags or paper towels to wipe the dye onto the wood.

Blot off the excess dye after 10 minutes. The dye will begin soaking into the wood right away. After you are done misting dye, use clean rags or paper towels to wipe away the remaining dye. Remember to work along the oak's grain. Wiping smooths out the coating and removes excess dye that can make the wood too dark.

Wait about 2 hours for the dye to dry. You will need to wait for the oak to feel dry to the touch. If the dye isn’t dried properly, it may discolor the final stain. The dye may also darken during this time, so waiting can help you get an idea of how much more dye the wood needs. Check the manufacturer’s instructions for drying recommendations.

Apply extra coatings of dye as needed. You may need to repeat dyeing 2 or 3 times to get the color you desire. Remember to wait for the wood to dry every time you add another coating of dye. The oak should be a consistent color when you are finished. Each coating of dye deepens the oak’s coloring, so be cautious. Reversing a dark dye job is very difficult and you may need to start over on new wood if this happens.

Sand the wood lightly with 320-grit sandpaper. Sand along the wood’s grain, pressing down very lightly to avoid scratching the oak. This scuffs the oak so it is better able to absorb sealant. Wipe off the wood particles with a clean, dry tack cloth when you’re finished. Use only fine-grit sandpaper. Anything coarser will damage the wood. Make sure you sand the entire area. Any areas that appear dull in light usually haven’t been sanded enough.

Brush dewaxed shellac onto the dye to seal it into the wood. You will need a can of clear shellac from a home improvement store. Look for the 2 pounds (0.91 kg) variety. Using a paint brush or clean rag, spread the shellac onto the oak, moving along the grain. The 2 pounds (0.91 kg) label on the can of shellac means that 2 pounds (0.91 kg) of shellac flakes were dissolved in alcohol. You can use sanding sealer or varnish instead of shellac.

Wait 30 minutes for the shellac to dry. The shellac should feel dry to the touch. Depending on how well-ventilated your workspace is, drying may take a little longer than this. Check the manufacturer’s instructions for the recommended drying time.

Applying a Gel Stain

Scuff the oak again with 320-grit sandpaper. Use the fine-grit sandpaper to scuff the area you dyed and sealed earlier. Press very lightly so you don’t rub through the shellac coating the wood. Sanding helps the gel stain settle over the shellac.

Brush gel stain onto the wood. The easiest way to apply the gel stain is with a foam brush, but you can use clean rags or paper towels as well. Spread the gel over the area you dyed earlier. The gel is thick, so you won’t be able to create a thin, smooth coating. As long as the entire dyed area is covered, the wood will stain properly. Visit a home improvement store to purchase gel stain. You can choose from many different colors to stain red oak. For example, you can use a dark walnut stain to color the oak golden brown. This shade goes well with honey amber dye if you used it earlier.

Wipe off the excess gel with clean rags. The gel will begin settling in right away. It’s important to pick up the excess gel as soon as possible to prevent the wood from getting too dark. Wipe the rags along the wood’s grain, removing as much of the gel as possible. The thinner you make the gel, the lighter the stain color will be. It is better to thin the gel now for a lighter stain, since you can always darken the stain later.

Let the gel stain dry for a day. Gel stains dry relatively slowly, so give the wood plenty of time before working on it again. Set it in a safe location on a counter or table in a well-ventilated area. The wood should feel completely dry to the touch before you begin working on it again.

Apply more coats of gel stain as needed. Check the stain’s coloring after it dries. It should look light and consistent across the oak. If you want the wood to be a darker color, coat the oak in more gel. You may need to do this 2 or 3 times to get the shade you desire. Always wipe off the excess gel right away and let the wood dry completely. If you use too much gel, you can wipe the oak with mineral spirits to thin the stain. This only works while the gel is wet.

Dry gel stain rags in open air before throwing them away. Gel stain is a flammable substance. Any brushes, rags, or clothing that touched the stain should be spread out on a non-flammable surface. Wait for these items to feel completely hardened to the touch. When this happens, you can put the items into the trash. Keep the rags out of direct sunlight so they do not combust. You can also fill a metal container with cold water and put the items in it. Seal the container, then take it to a hazardous waste disposal center in your area.

Seal the gel stain with shellac. Once you are done staining the wood, apply another coating of shellac. Paint it onto the oak, working along the grain. Make sure it is applied in a thin, even layer. Let the shellac dry for 30 minutes before finishing the wood. The shellac seals the gel stain’s coloring into the wood, protecting it. You can use the same shellac you may have used if you dyed the wood. Only use dewaxed 2 pounds (0.91 kg) shellac.

Sealing the Wood with a Topcoat

Sand the wood with 320-grit sandpaper. Wear down the wood so it can better absorb the sealant. Use a light touch, since you don’t want to break through the shellac.

Cover the oak with varnish or another finisher. Varnish can be used as a sturdy topcoat that protects the oak for years. You can try using a clear spar varnish. Dip a paint brush into the varnish, then spread it along the length of the wood. Continue this until the stained area is coated in a thin layer. You can use lacquer instead, which is durable and glossier but can discolor over time. Another choice is polyurethane, which can make the wood’s finish look brighter and protect it from water.

Let the finish dry for 2 hours. Protect the oak until the topcoat dries completely. Keep the area well-ventilated so air flows through the room, speeding up the drying process. Check the manufacturer’s recommended drying time, since this can change depending on what topcoat you use.

Apply a second layer of topcoat as needed. Check the topcoat layer by shining a light on the oak. You should be able to see the waxy finish on the wood. Make sure the layer looks smooth. If it isn’t, you may want to coat the oak in a second layer to finish the oak. Let the new layer of varnish dry completely before using the wood.

Comments

0 comment