views

Removing Old Stripping and Prepping the Frame

Remove any screws holding the old weather stripping in place. Metal weather stripping is held in place by screws. Check along the center of each piece to find the screws, then use a Phillips screwdriver to remove them by turning them counterclockwise. Once the screws are out, the weather stripping will be loose and easy to pull out as well. If you aren’t replacing metal pieces, then you can most likely peel off the weather stripping by hand. You can also remove weather stripping with a screw gun.

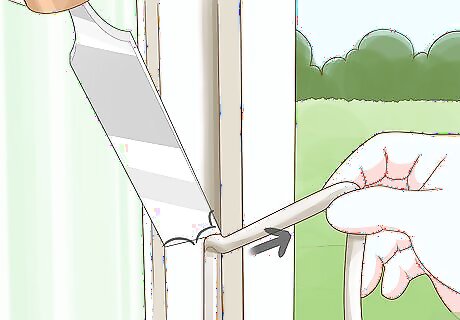

Peel adhesive weather stripping off the frame. Most types of weather stripping are very easy to remove without risk to your home. Grasp one end of the weather stripping, then attempt to pull it up. Adhesive material typically comes up right away. If it doesn’t, get a putty knife, pliers, or another tool to lift it up by force. You can also remove your old weather stripping with a sharp knife. To remove stuck adhesive weather stripping, slide a putty knife underneath one corner. Gradually push the knife toward the weather stripping to separate it from the frame. If you’re replacing screw-on weather stripping, pry it off. Set a pry bar underneath one corner and tap it with a hammer to wedge it underneath the weather stripping. Pry it up evenly on all sides.

Clean the door frame with soap and water to clear away debris. Mix equal amounts of warm water and a gentle dish soap, then scrub the frame with a soft cloth or sponge. If you removed adhesive weather stripping, make sure you eliminate any remaining glue or caulk. Some of it may be too hard to scrub off, so try scraping it off with a putty knife. Remove all of it so it doesn't get in the way of the new weather stripping. If you are unable to get rid of debris any other way, wear it off with fine-grit sandpaper, or 180 to 220-grit. With light but consistent pressure, rub the sandpaper across the frame. Let the frame dry before attempting to apply filler or paint. Wipe it down with a soft cloth or allow it to air dry for about 30 minutes.

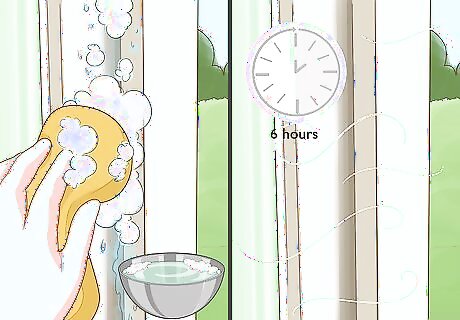

Fill in any nail holes using a paintable wood filler. These spots have to be filled in before you can install new weather stripping. Use a little bit, about a dime-sized amount of filler, for each hole. Pick it up with the edge of a flexible putty knife, then scrape it across the hole. Make sure all of the holes appear hidden and consistent with the surrounding wood before letting the filler dry for up to 6 hours. Note that some wood fillers have to be activated before use. Depending on the product, you will have to add water or knead it. Check the manufacturer’s instructions to get the filler to the proper consistency. Filler tends to shrink as it dries. To prevent the holes from showing up later, make sure they are well-covered. Use a little more filler than you think you will need, spreading it over the hole.

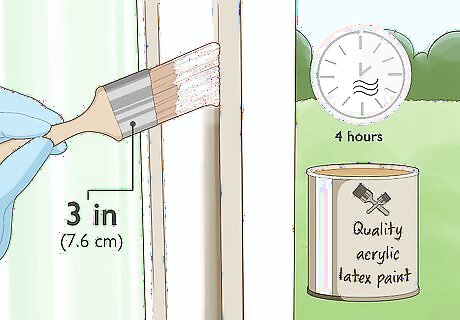

Repaint the frame to make it look fresh and consistent. Before painting, put on safety gear, such as a dust mask. Cover up nearby surfaces with plastic sheeting and painter’s tape as needed. Then, coat the frame with a quality acrylic latex paint and a 3 in (7.6 cm) paint brush. Finish the interior part of the frame, then go over the exterior portions on both sides of the door. If your frame is unpainted or has an oil-based finish, opt for an oil-based primer and paint instead. Alternatively, you could choose not to paint it at all and blend in the wood filler as best you can. Wedge doors and windows open while you’re painting. Remove any screens that could get in the way. You could also detach the door or window sash to make painting easier. Give the paint plenty of time to dry. Latex paints take at least 4 hours to dry, while oil-based paints can take as long as 24 hours. Check the manufacturer’s instructions.

Choosing Replacement Stripping

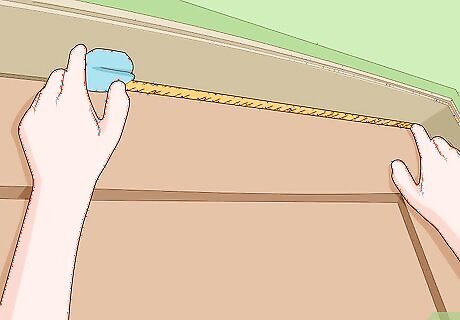

Measure the space between the frame and the door or window. By taking this measurement, you can figure out what size of weather-stripping fits around your door or window. Take separate measurements along the top and sides, since they will be different. Follow up by measuring the length and width of the frame. Keep these measurements with you so you are able to buy enough weather stripping at the perfect size for your project. If your old weather stripping is still intact, take it with you to a hardware store when shopping for new weather stripping. Ask store employees to show you to a suitable replacement. You could also measure the old stripping. Use it to purchase an identical replacement, or compare it to the frame measurements to ensure they are correct.

Choose felt adhesive strips for doors and windows you don’t often open. Felt strips are the most inexpensive type of weather stripping you can get. Unfortunately, they are also the least damage-resistant type available. However, they are still useful because they can be cut to size with a good pair of scissors and stuck to a frame without much work. Felt strips last about 1 to 2 years on average and may last longer on doors and windows you rarely open. Save felt strips for interior doors and windows in spare rooms you don’t use often. Exterior doors and main windows tend to get opened a lot and benefit from something more resistant.

Select a foam adhesive strip for longer-lasting protection. Foam strips are similar to felt strips but cost a little more. The main benefit of foam is that it’s also an adhesive tape that you can stick onto any frame. Since it’s a little stronger than felt, it lasts about 3 years on average. It’s a good option for doors and windows that get moderate amounts of use. Adhesive tapes can also be made of rubber. Rubber weather stripping has the same qualities as the foam version, so you can’t go wrong picking one or the other.

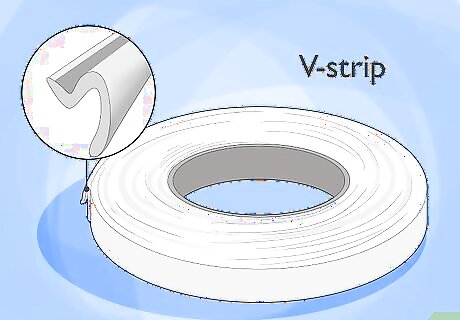

Select a nail-on V-strip for a longer-lasting seal. V-strips are made of either of vinyl or metal. The vinyl ones are less expensive and sometimes have an adhesive backing. The metal variety is meant to be nailed on, so it can be more difficult to install. V-strips are very effective at weatherproofing doors and windows, however. V-strips are meant to fit inside grooves between a door or window and its frame. If you don’t see these grooves, you won’t be able to install the V-strips unless you cut the grooves yourself with a router. Nail-on V-strips are very weather-resistant but sometimes require you to take down doors or window sashes to place them.

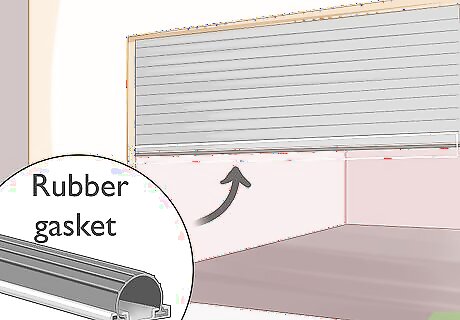

Choose a rubber gasket to seal the bottom edge of exterior doors. Rubber gaskets consist of a rubber half-circle attached to metal bars. The metal bars can be screwed to the door to hold the gasket in place. Some types of gaskets work with adhesives like caulk as well. They are great choices for weatherproofing door sills while also allowing the doors to swing open smoothly. Rubber gaskets are often used on garage doors, although they can be applied to regular doors in place of door sweeps. Door sweeps are similar to gaskets but have a slightly different shape. They fit along one side of the door. Most of them attach to the inside part of a house door, but some are designed to be placed on the exterior side.

Installing New Weather Stripping

Mark the weather stripping according to the size of the frame. Use your frame measurements to figure out what size each strip needs to be. Start with the sides and top of the frame. Use a tape measure to size the weather stripping, then mark it with a pencil. If you’re using the same type of weather stripping for the bottom edge of the frame, plan on cutting another piece for it. Most windows use the same weather stripping on all sides. Adhesive strips work very well, but you could also use nail-on stripping. For exterior house doors, use a door sweep for the bottom edge. Adhesive stripping typically isn’t used there.

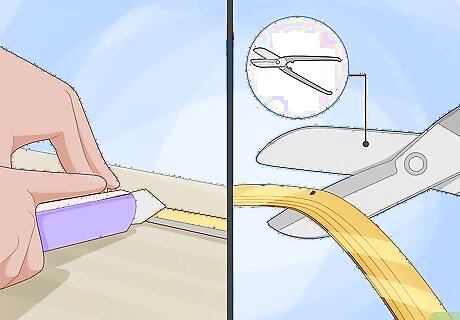

Cut the weather stripping to size with a utility knife or tin snips. Cutting weather stripping is very easy, but be careful to avoid bending the material out of shape. For adhesive material, cut it to size with a utility knife. Use a sharp pair of tin snips instead to make short work of metal weather stripping. Cut the material until you have pieces for all sides of the frame. You could also use a hacksaw to cut metal weather stripping. Wear proper safety gear, such as a dust mask and possibly protective glasses.

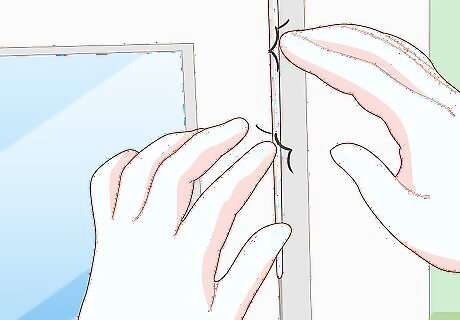

Position the weather stripping in the frame to test its fit. Start with the long pieces meant for the sides of the door or window. Most modern doors and windows have grooves in the frame, so center the weather stripping there. Place the remaining strips on the top and bottom. If you’re sealing a window, place the bottom strip first, then lower the sash to fit the top one. Open the door or window a few times to test it. Check that the weather stripping fits well and provides a good seal. Cut it as needed to make it fit. If you don’t see any grooves, stick the weather stripping between the wall and the door or window. You can usually cut grooves into the frame to better hide the weather stripping, but it’s not necessary.

Peel and stick the weather stripping in place if it is adhesive. Remove all of the weather stripping when you’re done testing it. Then, start with the sides of the door or window again. Peel off the adhesive backing on the stripping and press it against the frame. Take care of the sill if you’re using the same type of weather stripping on it, then fit the final piece against the top portion of the frame. Opening doors helps a lot when you’re weatherproofing them. You usually do not need to remove a door when applying adhesive strips to its frame. Keep windows closed as you apply the first strips. Slide the strips up through the bottom edge of the casing. Secure the bottom strip on the sill before lowering the window and applying the top one.

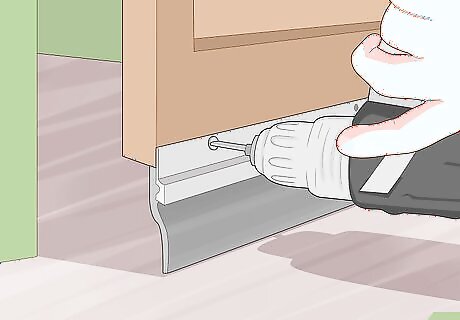

Nail weather stripping to the casing if it doesn’t have an adhesive backing. Metal stripping, for instance, has pre-made nail holes along its center. The weather stripping typically comes with the correct nails included. If you need to get more nails, look for 1.5 in (3.8 cm)-long finishing nails. Try getting copper-plated weather strip nails or a similar product that resists moisture. Some weather stripping uses screws instead of nails. Screws fasten the weather stripping in place more securely, but the attachment process is the same otherwise.

Attach the door sweep to the sill if you are using one. To finish weatherproofing a door, screw the door sweep to the door. The most common type of sweep is a metal and rubber strip that fits around the door’s underside. Position the sweep against the inside part of the door. Hold it in place and shut the door to test its fit. Then, drive the included screws through the holes in the sweep and into the door.To help ensure that the screws don’t crack your door, pre-drill some holes. Make the holes one size smaller than the screws. The screws will vary depending on the size of the sweep, so compare them to the drill bits you have available. If you’re applying regular weather stripping to the sill or sealing a window, you won’t need a door sweep.

Comments

0 comment