views

Preparing Your Materials

Decide what kind of shoe you would like to make. If you're planning on making a shoe, it's undoubtedly important you have some idea what kind of shoe you would like to make. Shoes are incredibly diverse, and there are plenty of types you can make, not limited to loafers, sneakers, sandals, boots and high heels. Try to imagine what kind of shoe style would suit your individual style the most. It may be helpful to sketch out a few ideas. Manifesting your ideas with an illustration can come a long way towards planning out your shoe. If you're new to shoe making, it's probably best to stick to something simple. A basic laced shoe goes without some of the finesse of more complicated types, and you can still add plenty of flair to a basic formula.

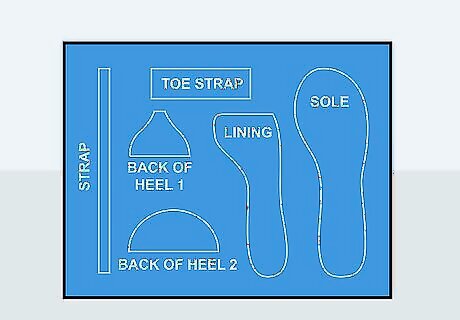

Design, find or purchase a blueprint for your shoe. Before you think about making your shoe, it's important you have an accurate and well-detailed set of plans to work on. After all, you don't want to be making design decisions on the go; shoemaking is a very precise business, and the slightest mishap could keep the shoe from turning out well. Basic shoe templates are available on the internet. Do a search and look up some 'recipes'. If nothing else, it might give you inspiration for your own design. Online art outlets like www.etsy.com may have more elaborate shoe templates for sale. Designing your own is only recommended if you've made a shoe before. If that's what you're ultimately looking to do, try stitching together something basic with a free template, and put that experience towards making your own the second time around.

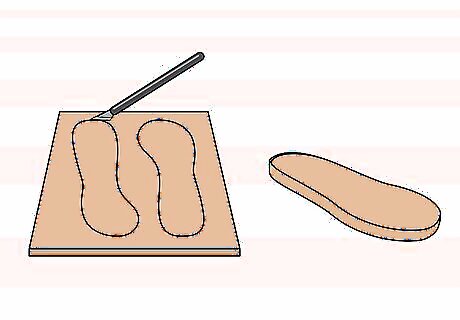

Harvest parts from old shoes. You can save yourself a lot of time and give your shoes a more professional look if you harvest parts from other shoes you don't use anymore. In particular, shoe soles are good as they'll give you a reference for the rest of your stitching. Provided they're in good enough shape, you should salvage the parts you think might work in your new shoe, taking care to remove them slowly and carefully with a scalpel knife.

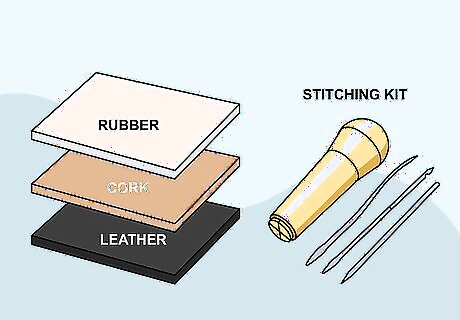

Get the rest of your materials from a hardware store or speciality outlet. While specific lists of ingredients will depend on the certain type of shoe you're looking to make, it generally goes without saying that you'll want a few sheets of good leather and a firm fabric. If you don't have a sewing and stitching kit, you'll need to buy or borrow one to make your shoes. Rubber, leather and fabrics are all good for the chassis of the shoes. While its recommended that shoe soles be taken from old shoes or bought as pre-fabricated supplies, you can make a functional and waterproof sole using a few sheets of cork. Each sheet need not be more than 1/8 inches thick. Remember to get at least twice as much as you think, so you'll have enough to make a pair!

Making A Foot Cast

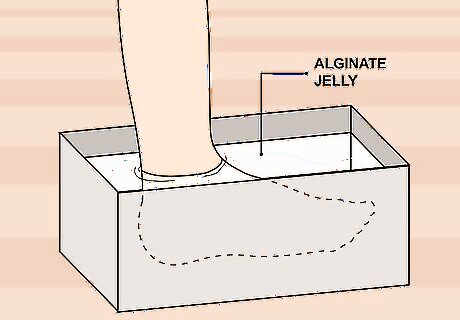

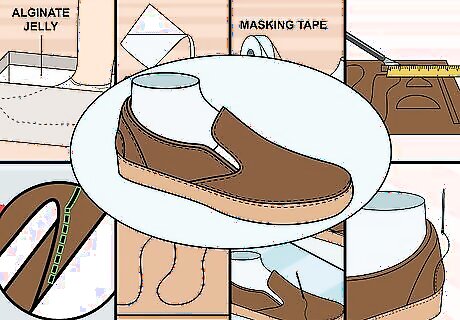

Make a custom last. A last is a block in the shape of a human foot shoemakers use to guide their work. To do this, you'll want to make a cast mould of your foot; that way, the shoes you'll be making will be custom-fitted for you personally. Get a box filled with an alginate jelly and place your foot in, ideally up to the ankle. Let your foot rest for 20 minutes while the jelly solidifies, then slowly remove your foot. Make sure to remove your foot slowly; you don't want to damage anything once it solidifies. It's highly recommended you do this for both feet at the same time. The idle time is best to get over with early on in the process. One positive thing to mention about this step in the process is that you can ideally reuse these lasts for each subsequent pair of shoes you try to make. Make a point of keeping them somewhere safe, where they don't run the risk of being broken.

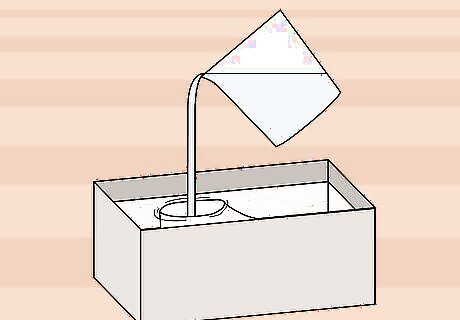

Pour casting material into your casting box. Now that there's a proper mould of your foot, you can pour casting material into it. Depending on the type and quality of casting material, the solidifying time could take anywhere from half an hour to overnight. Be patient-- it may be a good time at this point to work on other parts of the process if your plans are settled enough.

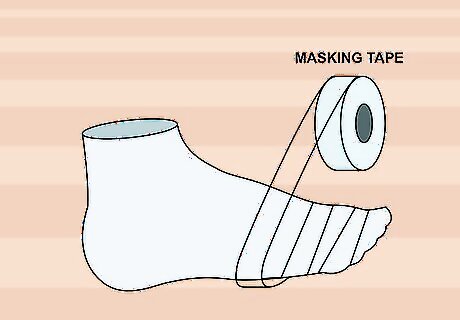

Remove and tape your last. Once the last has solidified, it's time to take it out and get it ready. Cover your last with a colourless masking tape. That will keep it from being damaged as easily, and you'll be able to draw your designs directly on the last. Outline your design on the last itself. Before you get to putting the pieces together, you'll probably find it helpful to give the last an outline of what you want the shoe to look like around it. While you shouldn't rely on it for concrete measurements, having an idea of what it will look like in three dimensions will help as you're figuring out where each stitch should go.

Assembling Your Shoe

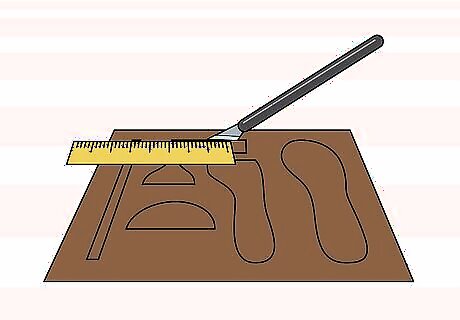

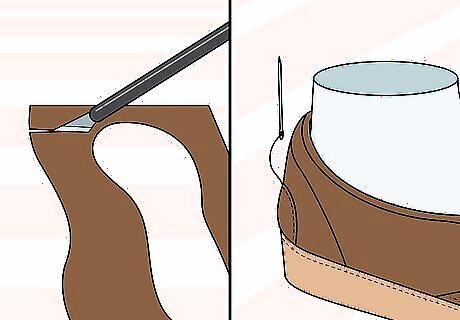

Cut out your leather and fabrics. Using your template or personal design, cut each necessary section of fabric or leather out using a surgical knife or scalpel. You may find it helpful to use a ruler or protractor to help you with the incisions. While cutting your pattern, you should leave at least an inch of extra material along the bottom edge of the shoe, as well as a centimetre or so, where the different pieces of the upper join together. This will be your seam allowance.

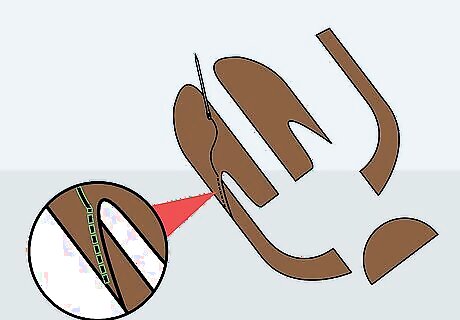

Stitch pieces together. A fluid stitch is one of the most skill-testing parts of making your own shoe. Be meticulous and slow as you're piecing it together; while it may be easier to go faster, bad stitching will certainly show in the final product, and your shoe won't look as good as it should. Try to get the stitches as close to the end of each piece of fabric as you can. Overlaps might leave unnecessary ridges on the shoe. If you intentionally cut your pieces to be slightly bigger than necessary for the sake of having stitching space, remember to take that into account. You don't want to end up with a shoe that's too big, or too small for the sole. While fabric won't be any problem to stitch through, you may have an issue with leather. Leather is notoriously sturdy, and you won't be able to stitch it fluidly. Rather, it's recommended you punch holes in it before connecting it to your other pieces.

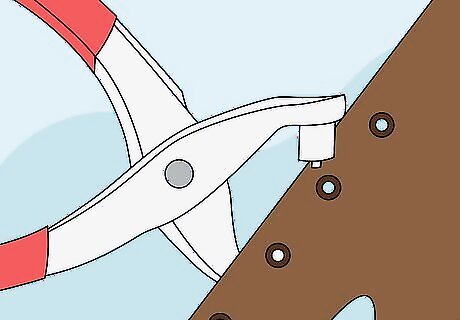

Make eyelets. Eyelets are the holes you'll need to fix your laces through. Chances are your shoe design will use these. Evenly space the eyelets apart from one another (just less than an inch, in most cases) and offer enough of them (4-5) to encase most of the laces. If you're the DIY type, you can make these incisions with a scalpel easily enough. If you're going for a more professional-looking product however, there are specific eyelet-making tools you can order from a specialty outlet.

Cut out your sole. If you purchased a pre-fabricated sole or nabbed a pair from old shoes, you won't need to worry about this step. If you're trying to make a purely homemade set of shoes however, picking up a few sheets of cork is your best bet. Cork has a comfortable amount of cushion, and it's waterproof. If you have the fabric stitched together already, you can use that as a point of reference while making your incisions, although you should ultimately rely on the empirical measurements laid out in your template. Your last should come in handy here as well. Cut the sole out of the cork sheet, leaving a little extra space around the last so your foot will ultimately have some breathing room. If you're wanting some extra cushion and height, you can add a second or even third layer of cork to your sole. Just cut it out in the exact same dimensions, and superglue the layers together. Give the glued cork soles some time to solidify once you've finished gluing them. You can make a shoe heel by adding an extra layer to the posterior third of the sole.

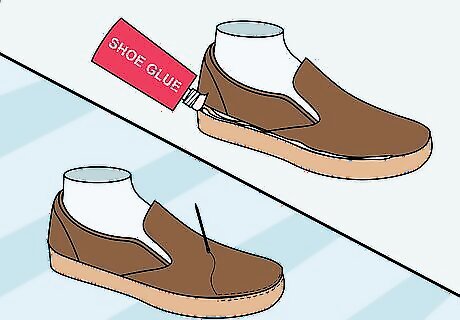

Stitch and glue your pieces together. Stitching the fabric to your sole won't work, at least not by itself. It's recommended you pick up a shoe-specific adhesive to glue your fabric to the sole. Apply the glue slowly and evenly. This will maximize the waterproof seal for your shoe, and keep it sturdy. If your blueprint suggests any additional stitches, do those as well. Make use of the last inside the shoe as you're putting it together. It will make a great point of reference and support while you're getting the tricky stitches done. If you're a real pro with stitches, don't be afraid to spice up your stitching style. Stitches themselves can be an interesting aesthetic tool. If you're feeling more daring than the rest of us, you can experiment with irregular stitching patterns, so long as they're fundamentally sturdy enough to do their practical job.

Trim excess fabric and add patches where desired. By this point, you should have relatively functional shoe. Add laces through the eyelets if you haven't already. To make the shoe look as good as it can be, you'll want to trim the excess fabric. If there are some really ugly seam marks on the shoe, you can add a new layer of leather or fabric to cover it up. Now that you have the body of the shoe, you can start thinking about adding more aesthetic flair to it.

Repeat the process for the other shoe. It's generally assumed you'll want to make two shoes to wear at the same time. After the basics of the first shoe are done, it's time to move onto the second. Keep in mind that you're not wanting to make a copy, but a mirror image of your original shoe. Try to keep it looking as close to the first as you possibly can. Any possible slip ups you made on the first will look worse if they're not reflected on the other shoe. If you were frustrated making the first shoe, you should find making the second is a lot more enjoyable.

Putting Finishing Touches on Your Creation

Waterproof your shoes with a sealant spray. A leather-based shoe will own with its own natural waterproofing abilities, but you're going to want to do everything you can to make sure water isn't able to get in. Getting a relatively inexpensive sealant spray and give your shoes a thorough going-over is a smart idea, especially if you live in a wetter part of the world.

Add decorative touches to your shoes. Let's face it; most of the time you're making something from home, it's because you want to put your own unique spin on it. You have plenty of chance to do so even after the shoe is made. Taking a leather paint and adding an inventive design to the sides of the shoes is a fun and effective way to add style to your creation. There are countless ways you can stylize your shoes. Look online for some ideas if you're in need of inspiration.

Take them for a test walk! Now that your spiffy creations are finally finished, it's time for the defining moment of trying them on and putting them to use. Try walking down the hallway or the street and get a hang for the way they feel. Are they comfortable? Do you think they could keep out water if you accidentally stepped in a puddle? If this is your first time making shoes, it's perfectly normal for there to be issues. If you're not satisfied with the end result, you can always put the expertise you've gained to good use and make another pair. If it's just the insole that's uncomfortable, you can buy gel-based insoles (like Dr. Scholl's) to give your feet some much-welcomed cushion.

Comments

0 comment