views

Setting up for Success

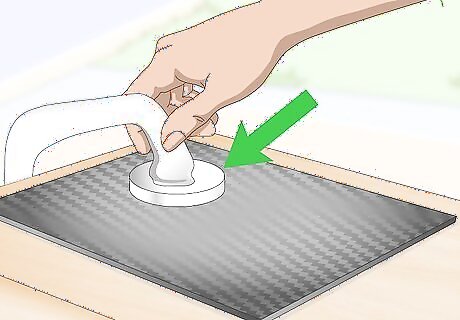

Clamp the carbon fiber tube or sheet a workbench. A downdraft table works really well if you have one, since you can use the built-in ventilation system to suck away the carbon fiber dust as it is produced. If you don’t have a downdraft table, cut the carbon fiber on any sort of flat surface. Use a clamp or vise to pin the piece of carbon fiber in place. To protect the work surface from damage, lay a piece of foam down and cut the carbon fiber on top of it. You may be able to cut carbon fiber without using a clamp. Bracing the carbon fiber with your hand, a straight edge, or another surface can help you cut it cleanly, especially if you're using hand tools. Whatever you use, make sure the carbon fiber piece cannot slip out of place while you make the cut.

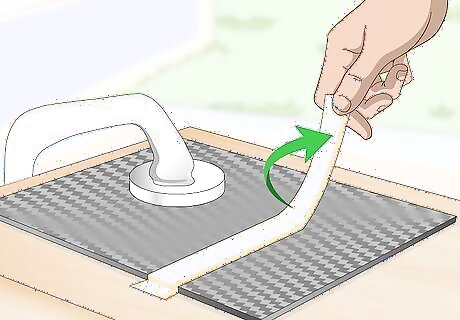

Use masking tape to outline the area you wish to cut. Carbon fiber is a dark gray or black color, so regular pencil won’t show up well on it. First, measure out your planned cut with a ruler. Then, lay down multiple pieces of tape to form a border around the area to be cut. This works particularly well for rounded surfaces like carbon fiber pipes. You can also use a marking tool such as a silver permanent marker. Combine it with the tape for extra precision.

Wear a dust mask and eye protection to avoid carbon fiber dust. Although it is considered to be nontoxic, carbon fiber dust will still irritate your eyes and lungs. You should always put on quality protective gear before cutting carbon fiber. Ventilate the area as much as possible to eliminate the dust. Using the ventilation system on a downdraft table helps a lot if this option is available to you. You may also be able to set up a vacuum hose near your workbench to suck up dust as you cut the carbon fiber.

Put on a pair of long gloves to avoid cuts and irritation. Cut carbon fiber is often very sharp, so have a good pair of reinforced gloves available. In addition, longer gloves can stop carbon fiber dust from accumulating underneath your fingernails and between your hands. Wearing long-sleeved clothing can help protect the rest of your body and is useful if you plan on cutting large amounts of carbon fiber.. If you do get carbon dust on your skin, you may feel a stinging sensation. Rinse the area immediately under cold water.

Using a Rotary Tool

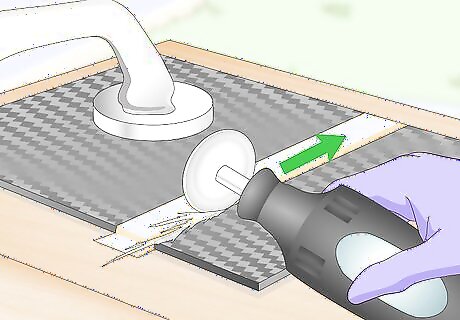

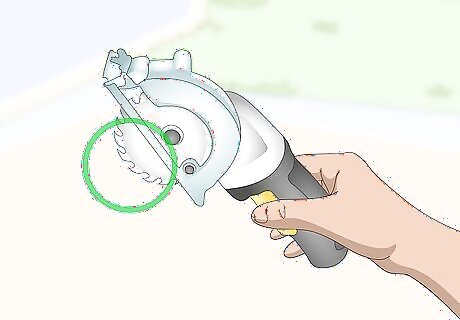

Get a diamond or tungsten carbide cut-off wheel or drum. You can use various rotary tools to cut carbon fiber, including a Dremel, pneumatic rotary, router, or angle grinder. Whatever you choose, make sure the wheel or drum is listed as being abrasive or grit-style. Smooth wheels and drums are less likely to get stuck or overheat than ones with teeth. Any wheel or drum designed to cut metal will work. However, these lower-grade cutters will not last as long as ones made from diamond or tungsten carbide and can clog up with the resin used to make the carbon fiber. Rotary tools are very useful for making straight, smooth cuts. Many times, they are a better and quicker choice to use on carbon fiber than saw blades.

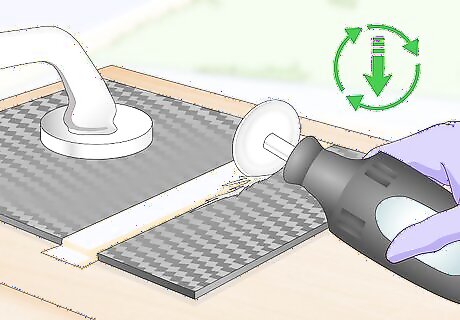

Cut the carbon fiber from the top down. After positioning the carbon fiber tube or sheet on your cutting surface, lower the rotary wheel onto it. You can cut right along the guiding line you traced on the carbon when planning out the cut. Keep the saw on the side of the line closest to the part you plan on discarding. When the rotary tool passes all the way through the carbon fiber, continue moving it along the piece until you complete the cut. A good rotary blade will cut through the carbon fiber quickly and smoothly, so you can cut right along any guiding lines you traced.

Slow the blade if it begins to overheat. This often happens when the rotary tool struggles to cut through the hard fiber, especially if you are using a common metal wheel. A few signs of overheating are loud squeals, a loss of cutting power, a burning smell, or smoke. If you suspect that the tool is overheating, move it away from the carbon fiber and shut it down until it cools. Avoid rushing your cuts. Give your tools plenty of time to cool down when needed.

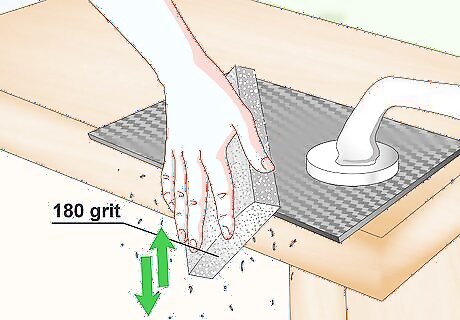

Smooth out cuts with a 180-grit sanding block. Rub the cut edge down briefly to even out the cut, removing any excess material around the guiding line you traced. This should also eliminate any sharp edges. When you’re done, examine the carbon fiber closely to look for any uneven parts and use the block to smooth them out. You can also use a file to hone and smooth out the carbon fiber.

Cutting with a Saw Blade

Find a saw with a tungsten-carbide grit-style blade. The teeth are the biggest issue with cutting carbon fiber with a saw. Blades with large teeth will chip the carbon fiber, while blades with smaller teeth will clog with resin and wear out faster. Harder blades that have finer teeth or no teeth at all and are designed for use on metal or carbon fiber are your best option. You can use jigsaws, saber saws, and even hand saws in conjunction with a tungsten-carbide grit-style blade. Electric saws may cut even faster than rotary tools, but the back and forth motion used will cause the edges of the carbon fiber to chip more. Hand saws, such as hacksaws and coping saws, tend to wear out quickly when used on carbon fiber. In addition, you may need to drill through the carbon fiber first to start an interior cut. If you need to cut a curve or a round shape, a saw blade is more effective than a rotary tool.

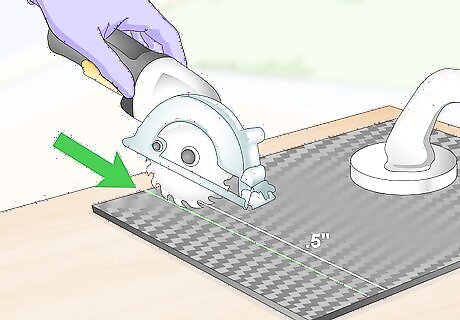

Position the saw blade ⁄2 in (1.3 cm) inside the line you traced. Because saw blades cause more chipping than rotary tools, cutting close to any guidelines you traced is risky. Instead, position the blade a little bit away from the line, if possible. Continue using the line as a guide while you cut through the part of the carbon fiber you don’t mind damaging. The excess material can be worn off with a sanding block or file.

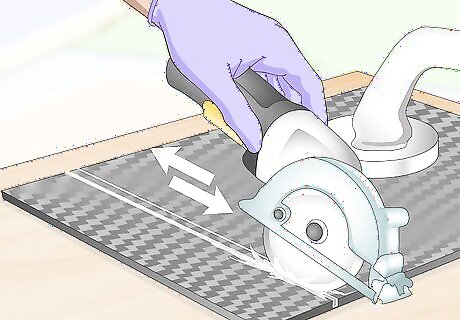

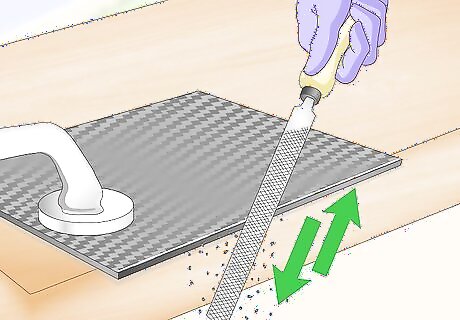

Saw through the side of the carbon fiber tube or sheet. Cutting carbon fiber with a saw is like cutting any other material. You can’t saw top-down like you can with a rotary wheel. Instead, move the saw back and forth to gradually cut through the fiber. Continue doing this until you complete the cut. Remember to keep the saw blade a little bit ahead of any guiding lines you traced to avoid damaging the carbon fiber’s finish. This will leave some excess material, but removing it isn’t too difficult.

File away the remaining carbon fiber material near the cut. Finish the job with a metal file. File away excess material on the cut edges until you reach the guiding lines you traced. When you are done, the edges should look and feel smooth and even. You can also use a sanding block. Get a block with a 120-grit side and a 180-grit side. The, you can use the rougher 120-grit side to wear away the excess carbon fiber and the finer 180-grit side to smooth the edges.

Comments

0 comment