views

Lifting the Truck

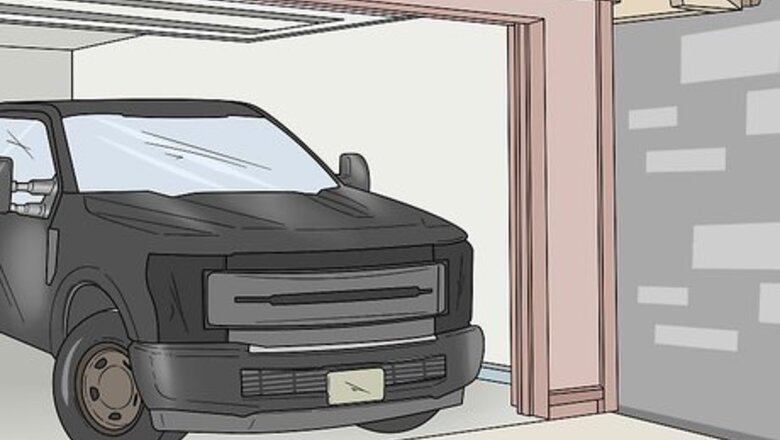

Park the vehicle on a hard, level surface. A garage, driveway, or quiet parking lot are a couple of options. Level, stable ground prevents the vehicle from moving while you’re working on the tire. Also, pick a secluded spot where you won’t be disturbed by other vehicles. Hard surfaces are always better than soft ones. Soft soil, for example, may not be able to support the truck’s weight, causing it to fall off a jack. The spot you choose is an important part of changing a tire safely. If you don’t feel safe where you are, you are better off calling for a tow truck.

Place chocks around the wheels to prevent the truck from moving. Chocks are small rubber blocks you can wedge underneath each wheel. Place a chock in front of and behind each tire other than the one you want to change. If you don’t have chocks, use bricks or wooden boards instead. Make sure they are firmly wedged underneath each wheel so it can’t rotate at all. Auto part stores sell chocks, but you can also get them online. They are inexpensive but very effective at keeping you safe while working on a truck. You can also engage the truck’s parking brake for additional safety.

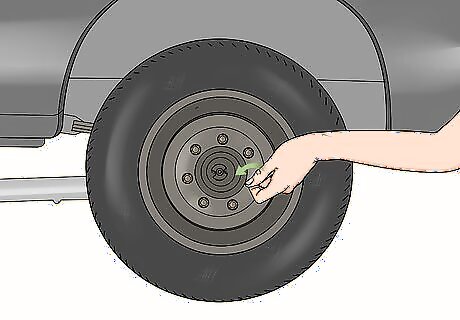

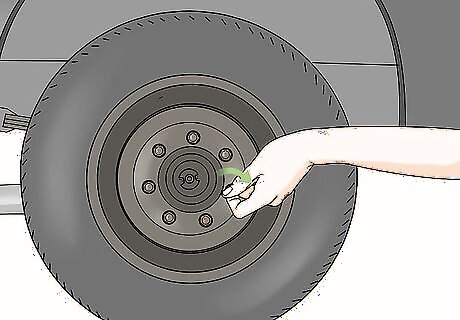

Use a screwdriver to pry off the hubcap if your truck has one. Most truck wheels have a metal cover over the lug nuts. If you don’t see exposed lug nuts, then you have a cover to remove. Slip the tip of a flathead screwdriver between the metal cover and the rubber tire. Then, pry the cover toward you in a few different spots to pop it off of the wheel. Some hubcaps are held in place by lug nuts. Using a lug wrench, loosen all of the nuts gradually and evenly until you are able to remove them. Most pickup trucks and flatbeds have hubcaps. Bigger vehicles, including semi trucks, often have a mix of covered and uncovered wheels.

Turn the lug nuts counterclockwise with a lug wrench to loosen them. Fit the open end of the lug wrench over the nuts one by one to begin removing them. They can be difficult to move at first, but keep trying until you no longer feel any resistance. You may need to step on the wrench or throw your body weight into it to break the lug nut free. Once you feel it come loose, stop turning it and leave it on the wheel. If you’re having a hard time getting stubborn lug nuts to turn, spray a rust-busting lubricant like WD-40 on them. Lug wrenches are fine for pickups and flatbeds, but you will most likely need something stronger for bigger vehicles. Try using a breaker bar if you’re doing it manually. For an easier way to detach the nuts, get a 1 in (2.5 cm) cordless impact wrench. It’s a handheld tool similar to drill, but it has an open end meant to fit over lug nuts.

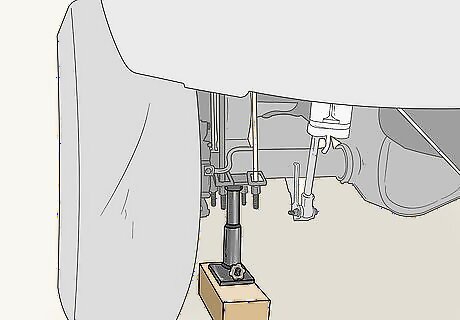

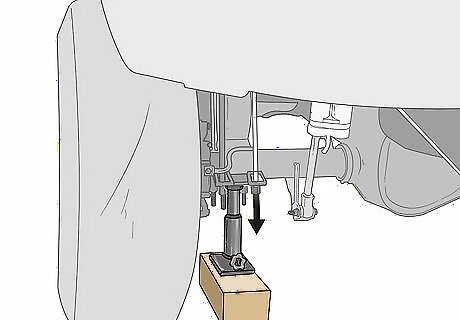

Raise the truck up by fitting a jack under it. Select a jack that is strong enough to support the truck’s weight, such as a hydraulic bottle jack. Many vehicles have notches near the wheel wells indicating a safe spot to place the jack. When using a bottle jack, pump the handle up and down to raise the truck. Lift it so the wheel is about 6 in (15 cm) off the ground. For safety, position the jack along a metal part of the frame rather than the plastic exterior. Check the owner’s manual if you are unable to locate the jack point just by looking at the truck. To lift heavier trucks, including dump trucks and similar haulers, use a hydraulic lift instead. Park the truck on the lift, then pump the handle to raise it. The biggest lifts are capable of supporting the additional weight. Really big trucks like semis often don’t need to be lifted. The other wheels are capable of supporting the truck’s weight.

Fit jack stands underneath the truck next to the jack. Pull the jack stands up so they reach the bottom of the truck. Then, slide them into place, making sure they are supporting the truck’s metal frame. The jack stands support the weight of the truck so it can’t fall off the jack. Use at least 2 jack stands to hold up the truck and prevent it from falling off the jack. Consider using 4 or more jack stands, especially when dealing with anything heavier than a standard pickup truck.

Replacing the Tire

Remove the lug nuts by turning them counterclockwise by hand. Now that you have the tire off the ground, you are ready to start pulling it off the truck. The lug nuts come first and should be easy to remove since you loosened them earlier. Twist them as much as you can by hand. If you are unable to remove them all of the way, finish the job with a lug wrench or breaker bar. Spray a lubricant like WD-40 as needed to loosen stubborn nuts. You most likely won’t have to use any once the nuts are loose, but have a bottle on hand just in case. Having an impact wrench makes the removal process much easier, although you won’t need it unless the nuts are really stuck.

Pull the wheel off of the truck and set it on the ground. Wheels are heavy, especially for bigger trucks, so take your time. Once the lug nuts are off, you should be able to pull the tire toward you. Grip the top and bottom of the wheel, then pull it toward you. Wear gloves to keep your hands clean and maintain a firmer grip on the wheel. Some trucks, including semis and some pickups, have double wheels. If you need to access an interior tire, pull it off after removing the exterior tire. You may need to get on your back and go under the car to undo the nuts.

Mount the new tire on the truck’s lug bolts. Line up the holes in the wheel with the lug bolts in the wheel well. After sliding the wheel onto the bolts, push it back as far as you can. If you’re replacing a double wheel, fit both wheels onto the lug bolts. Slide the inner wheel back, underneath the truck, before pushing the outer wheel into the wheel well. Positioning the new tire can be tough, especially with bigger trucks. Consider asking someone to help you lift the tire onto the axle.

Reinsert the lug nuts and tighten them by hand. Don’t tighten them all the way yet. Turn them as far clockwise as you possibly can by hand. This will secure the wheels to the truck so you can begin removing the jack and jack stands. Make sure the lug nuts are secure so the tire can’t fall off while you’re lowering the truck back down to the ground.

Lowering and Securing the Tire

Pull the jack stands out from under the truck. Use the jack to raise the truck by 1 in (2.5 cm). This will give you some room to reach underneath the truck and slide the jack stands toward you. Collapse the jack stands so they are easier to store. Make sure the truck is stable on the jack before attempting to reach underneath it.

Lower the truck by operating the jack. If you’re using a bottle jack, remove the handle and attach it to the metal valve near the jack’s base. Pump the handle to gradually bring the jack down until the truck’s tires touch the ground. For a hydraulic lift, lower it until the truck is back on the ground. Don’t remove the jack yet. Wait until you have finished tightening the lug nuts with a lug wrench or breaker bar to ensure the new tire is secure.

Tighten the lug nuts by turning them clockwise with a lug wrench. Once the new tire is on solid ground, finish securing all the lug nuts. Tighten them until they can no longer be moved. Test the nuts by attempting to remove them by hand. If you are able to turn them, then you haven’t tightened them enough. Use your foot or body weight as needed to help turn difficult nuts. Switch to a breaker bar or impact wrench if you aren’t working on a pickup truck. Remember that bigger trucks can have as many as 10 lug nuts. Make sure you get them all!

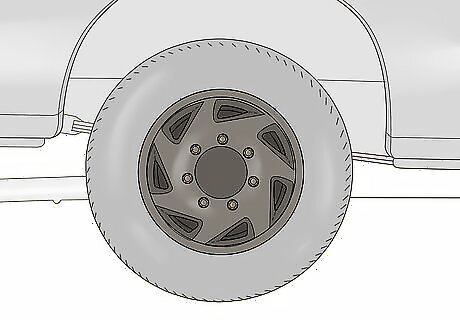

Replace the hubcap if the wheel had one. Many hubcap wheels fit directly over the side of the wheel and don’t require any special tools to replace. Line up the notch on the hubcap with the valve stem, then push the hubcap onto the wheel. Start with the bottom edge, fitting it against the bottom rim of the tire. Then, fit the upper part against the tire, tapping it into place with a rubber mallet or the soft part of a hubcap removal tool. Some hubcaps screw into place. If you have this kind, fit it over the lug bolts before putting the nuts back into place. Keep the jack underneath the car until you’re done with the installation.

Comments

0 comment