views

Detecting Problems While Driving

Pay attention to changes in air temperature. One of the most common symptoms of a fan clutch on the outs is an inability to properly cool the air circulating through the vehicle. Switch on the A/C and turn it down to the coldest setting. If it fails to cool down after several minutes, or seems to be emitting unusually warm air, there could be a problem. Hold your hand a few inches away from the vent so slight variations in temperature will be more noticeable. It may be a good idea to check the temperature of a few different vents. If the air flow feels suspiciously hot or weak, it could just be a bad vent.

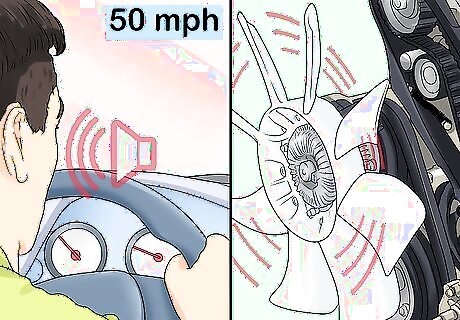

Listen for excessive noise when driving at high speeds. When a fan clutch binds, or locks up, the air passing through it can produce a gentle roar that’s audible from inside the cabin of the vehicle. The next time you’re driving about 50 mph (80 km/h) or higher, take note of how the fan sounds. Activity that’s louder than normal may indicate binding. A binding fan clutch will typically be accompanied with warm air flow from the A/C, since the fan isn’t turning the way it should be.

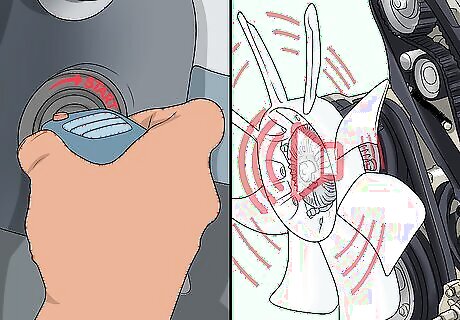

Start your vehicle and listen for the fan to engage. Give the engine a little time to warm up. After 4-5 minutes, the fan clutch should come to life. Assuming it doesn’t, or that it’s sluggish when it finally gets moving, it may be on its last legs. The same is true if the fan speed accelerates as soon as you start the vehicle. If the clutch does not engage when the AC is turned on when a voltage is present is a sign that the fan is damaged. Some fan clutches are designed with a built-in thermometer somewhere on the instrument panel. If your unit has one, keep an eye on the temperature so you’ll know about when the fan speed should begin ramping up. If the fan still hasn’t kicked in by the time temperature reaches about 200 °F (93 °C), you can be sure that there’s a problem somewhere. You should be able to hear it from where you're sitting inside the cabin of the vehicle. If the noise from the engine is too loud, try popping the hood to prevent the sound from being muffled.

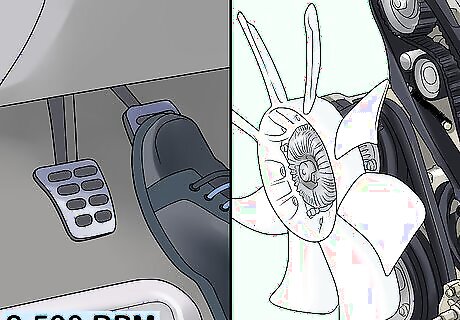

See if the fan slows or stops when you increase your speed. Press down on the accelerator gradually to bring the vehicle up to highway speed while you monitor the movement of the fan clutch. Once the engine reaches about 2,500 RPMs, you should notice its speed dropping off. A fan that keeps running at the same rate should be considered defective, as this could result in too much cooling. You can also perform this test while the vehicle is parked and in neutral gear. Most fan clutches on newer vehicles are designed with a metal spring coil that reacts to changes in temperature and engages or disengages the fan accordingly. This means that the fan should power down at higher speeds because the rushing air is sufficient for cooling the engine.

Inspecting the Fan Clutch Manually

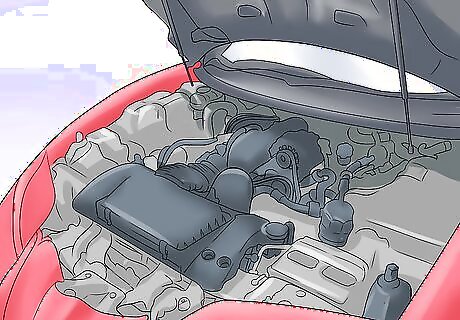

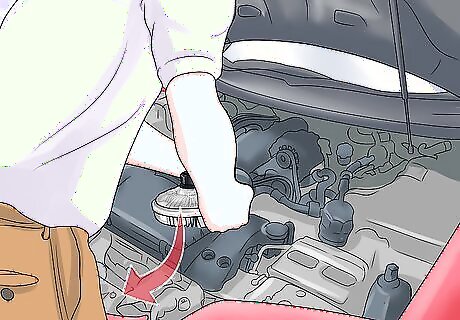

Pop the hood. Before you go looking for your fan clutch, make sure your vehicle is in park, with the engine off and the handbrake firmly engaged. If necessary, use the hood strut to hold the hood up so you can work unobstructed. Never attempt to inspect or handle any of the mechanical components in the engine compartment while the engine is running.

Locate your vehicle’s fan clutch. You'll find the fan clutch bolted to the water pump at the front of the engine compartment, between the radiator and the engine. The entire unit is only about 1 foot (30 cm) tall by 1 foot (30 cm) wide, most of which is the circular fan component. The outer housing may make your vehicle's fan clutch slightly larger, and can be either round or rectangular. When the engine starts to get too hot, the fan clutch takes the air flowing through the radiator, cools it down, and feeds it into the engine to cool it. Standard thermostatic fan clutches will only be present on cars and trucks with rear-wheel drive. Front-wheel drive vehicles are equipped with a completely different cooling system due to the way the engine is configured.

Examine the unit’s general condition. You’ll be able to tell right away if something is out of place or there’s any major structural damage. On a functional fan clutch, the fan blades will all be lined up neatly inside the housing, which should sit upright with an equal amount of space between the radiator and engine. Check to make sure each of the bolts holding the fan clutch in place is secure and intact. Keep an eye out for any visible components that are bent, crooked, or missing.

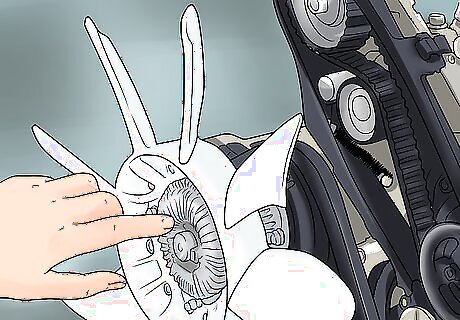

Feel for excess movement in the fan and housing. Wiggle each of the fan blades individually to see if they feel damaged or displaced. Do the same for the metal housing that surrounds the fan itself. Loose, rattling pieces send a loud and clear message that you need to have your fan clutch replaced. In most cases, fan blades are designed to flex up to ⁄2 inch (1.3 cm). Any more than that could compromise the efficiency of the unit. Give the water pump hose a quick jostle as well to see if the problem might lie there.

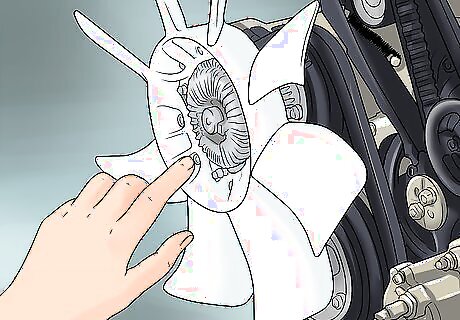

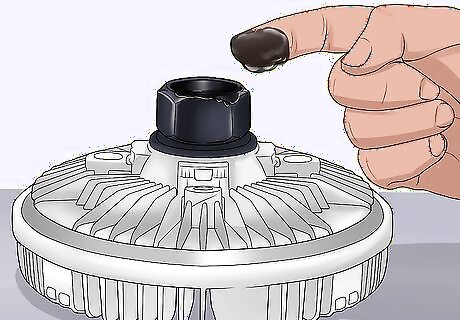

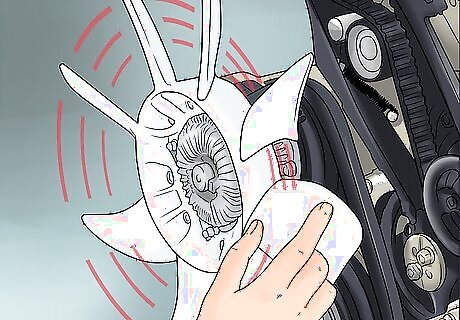

Spot-check for oil leaks. Run your finger along the edges of the bearing seal on the backside of the fan clutch. If it comes away with a heavy coating of oil, the culprit is either a crack or a faulty seal. Radial streaks are another potential clue—this happens when oil escapes from the clutch and is then blown outward in all directions by the fan. Inside the fan clutch, there is a small reservoir filled with a viscous silicone-based oil. The oil flows to and from the main chamber as engine heat fluctuates, engaging and disengaging the clutch. Traces of oil are perfectly normal, and won’t necessarily be an indication that your clutch is shot.

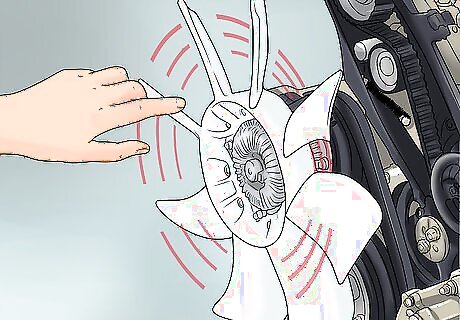

Turn the fan by hand. Grab the edge of one of the blades and give it a good push. While there should be a little bit of give, it shouldn’t spin more than three complete rotations. Too much free-wheeling is usually a sign that the clutch is prone to slipping. On the other hand, too much resistance means the clutch is binding and can’t turn freely. In either case, it will need to be replaced. Ideally, the fan shouldn’t spin more than 1-1½ times. For your own safety, you should never attempt to manually test your fan clutch while the vehicle is running.

Have your fan clutch replaced by a professional. Once you think you’ve uncovered the source of the problem, take your vehicle to a trusted garage for repairs. A qualified mechanic will be able to confirm your findings and take the necessary steps to get the clutch working correctly again. They might even be able to turn up other potential complications that you didn’t catch. It will cost somewhere between $150-300 to have a new fan clutch installed, on average. Make sure your new fan clutch is the same type as the original. It’s possible to upgrade from a non-thermal clutch to a more efficient thermal model, but not the other way around.

Comments

0 comment