views

Removing the Old Camshaft

Check the user's manual for your vehicle for specific diagrams. Engine assemblies vary drastically from make to make and model to model, so it's impossible to offer a generalized guide for installing every camshaft. For this reason, it's important to invest in a Haynes guide, or another official user's manual with rebuild schematics specific to your make and model. It's possible to seriously damage your engine and wreck the timing if you don't use a detailed manual for this job. Read on only for a general description of the steps of the process.

Determine whether or not you need to pull the entire engine. To access the crankshaft compartment, you may have to pull the entire engine, depending on the type of engine and the make of the vehicle. Overhead Camshaft (OHC) engines are much easier to access than Overhead Valve (OHV) type engines, with the camshaft centered in an engine block. Most American-made V8 and V6 engines use in-block camshafts, which means you may have to pull the engine out to do the swap. Many engines using overhead camshaft configuration actually have multiple camshafts, such as a Dual Overhead Camshaft (DOHC). If you have a DOHC engine which is also a "V" configuration it is possible to have as many as 4 camshafts.

Access the camshaft. Removing the timing cover is one of the most difficult parts of an in-car installation, if you're going to attempt it without pulling the engine. The oil pan must be lowered enough to remove the timing cover while also clearing the crankshaft snout. With the cover off the engine, remove the three upper timing-chain bolts, along with the lower timing gear if a new timing chain is to be installed. This process will vary, depending on your make and model, but generally you'll have to start by disconnecting the battery lines, then removing the radiator cap and releasing the valve under the passenger's side to drain it. Once the coolant is drained and the accessories are out of the way, remove the intake-manifold bolts. A small hammer and chisel or flat-head screwdriver may be needed to pry the intake manifold from the engine block. Scrape the front and rear block rails clean of cork, silicone, oil, or any other gunk, if necessary.

Remove the valve covers. This will allow you to access the rockers, pushrods, and lifters. Keep the rockers and pushrods in order. While you remove the rocker nuts, the engine may have to be turned over a few times in order to take valve spring pressure away from certain rocker-to-valve stem contact points. Remove the Mass Air Flow (MAF) and Intake Air Temperature (IAT) sensor assembly, if necessary. Unbolt the radiator tray and remove it. Unbolt and detach the Manifold Air Temperature (MAT) tubes from the manifold. Remove the spark plug wires, disconnecting the wiring harness leading to the coil packs and remove the coil packs from the valve covers. Detach the hoses from the valve covers and remove the valve covers to access the crankshaft.

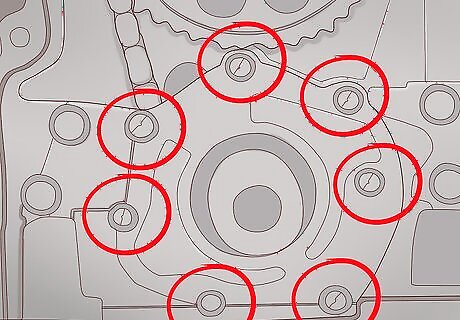

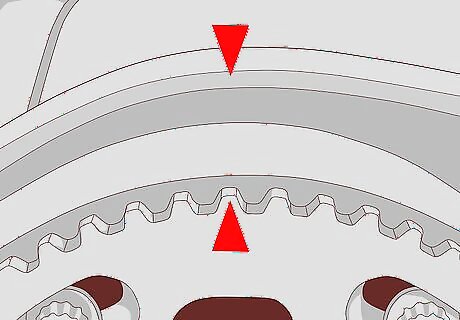

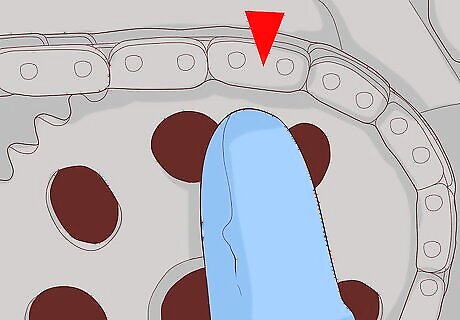

Rotate the cam and mark Top Dead Center (TDC). Turn the camshaft wheel until you see the V-shaped timing mark at the top. If these timing marks are not aligned properly during assembly, the camshaft will be out of phase with the crankshaft and the valves may be damaged if they strike the pistons. If you need to adjust the timing afterward, you'll be able to make specific tweaks, but it's still good to make sure you've got the mark recorded so you can install the cam safely.

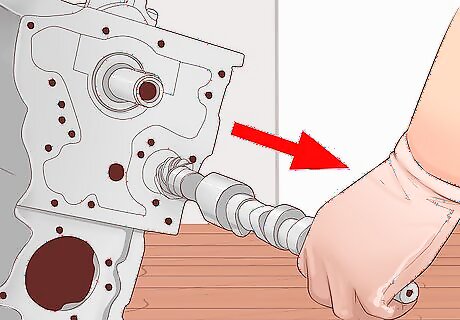

Remove the old cam. Though using a camshaft removal tool is ideal, if your budget is tight you can work the cam out of the engine block by twisting it slowly and carefully, taking precaution not to scratch or gall the bearings. If you want to change the timing wheel, chain, or any other components in the assembly, you'll also want to remove these, correspondingly.

Installing New Camshafts

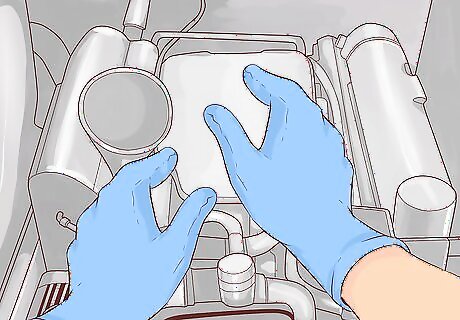

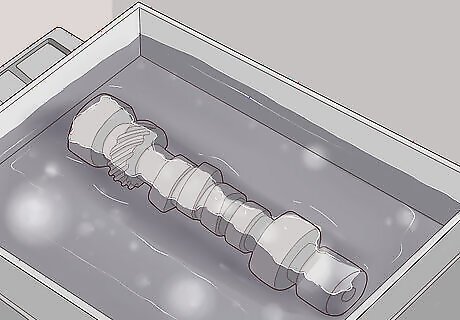

Wash new parts in solvent before installation. The camshaft and valve gear components should be washed in solvent, to remove grease and dust accumulated during transport, to ensure a clean installation. Dry the parts thoroughly before installation, laying them out on paper towels or shop rags. Don't soak hydraulic lifters, which will be compromised by cleaning solvents. Before installing your new camshaft, make sure to check the part numbers of the camshaft and valve gear components against the manual, to avoid any mismatch of equipment due to a shipping error or a mistake at the shop.

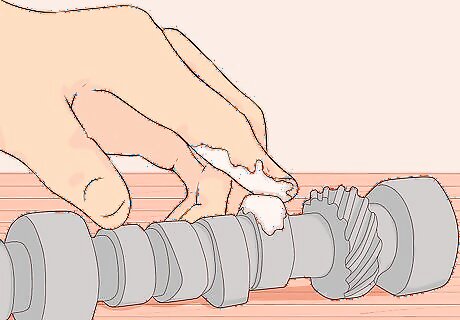

Lubricate the cam. Cam lobes and bearings need to be coated with oil conditioner, which is usually included with new part kits. Rotate the cam while it's in the block, applying the oil in small amounts. Be careful to avoid scratching the cam bearings. Move the cam as far back as the plug at the rear of the block will allow, and fasten the upper timing gear.

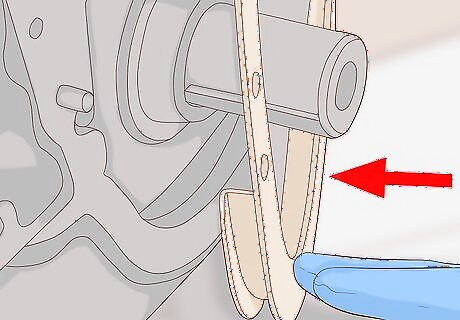

Set the timing chain. The timing chain and sprocket can be assembled after you've lubricated the parts. To align the timing, you need to set the timing gear to Top Dead Center (TDC) and torque the assembly to the proper specifications, which will differ, depending on the brand of the component. Most gears will be marked with a notch or a green dot to help set TDC. Rotate the gear until the mark is at roughly 12 o'clock. Always defer to the manufacturer's directions. With the camshaft in place, the upper timing gear should have its timing dot in the 6 o'clock position; the lower timing gear should show its zero-degree marking in the 12 o'clock position. Checking this will ensure proper valve train movement and allow the engine to respond the way the camshaft is intended to.

Position the lower portion of the timing cover over the oil pan. Make sure oil does not leak from the front of the engine. Apply silicone between the oil pan and timing-cover seal contact points, then tighten the oil pan back into place. If the gasket is undamaged, it can be cleaned before spreading a thin layer of silicone between the pan and the block.

Lubricate and install the lifters. Always use a new set of lifters, checking each to make sure it can move unimpeded after you assemble it. If it doesn't, the cam and lifter will be distributed incorrectly, which can result in engine failure. Lubricate each of the the new lifters, dropping them into their place. Install the pushrods through the cylinder heads, install the rocker arms, and put the pushrods against the rocker cups.

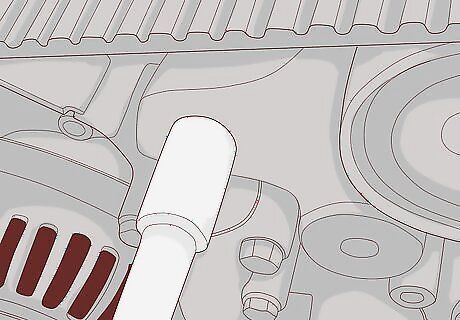

Reassemble and reinstall the rest of the assembly. Reinstall the water pump and reconnect both heater hoses. Compress the belt tensioner and replace the drive belt. Reinstall the radiator and refasten all of those hoses, reconnecting the tubes in the fill neck. Secure the wiring harness to the fan shroud and replace the radiator tray and the MAF assembly. Refill the radiator with a 50/50 mix of coolant and water. Inspect the engine for any loose connections and then reconnect the battery cables.

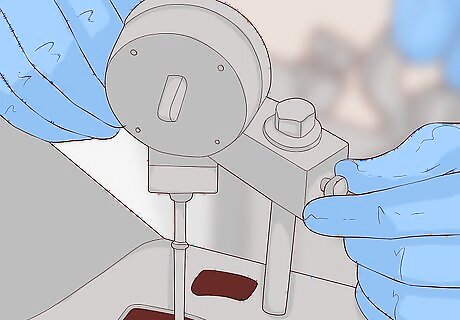

Test the timing and adjust if necessary. Turn the ignition and let the engine run, without starting, for a few seconds. Reconnect the coil pack harness if there are no problems. You may need to adjust the timing, using a timing gun, if you want to optimize the cam function.

Start the car to verify that the oil pressure is stable. Let the car idle, pressing the gas pump if it threatens to stall. When the engine is running at full temperature, replace the radiator cap.

Comments

0 comment