views

Drilling through the Rivet

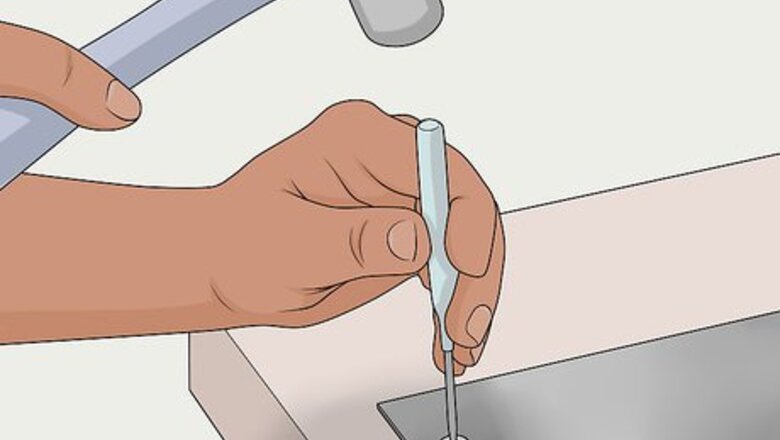

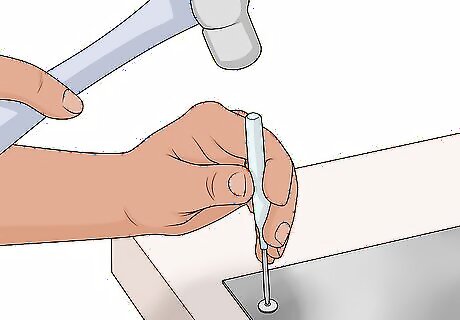

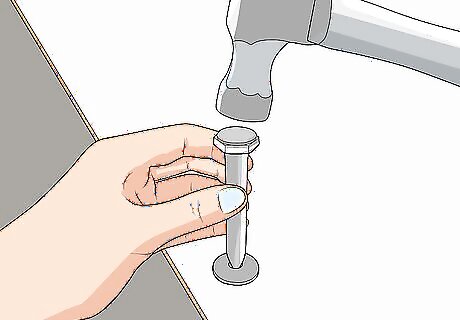

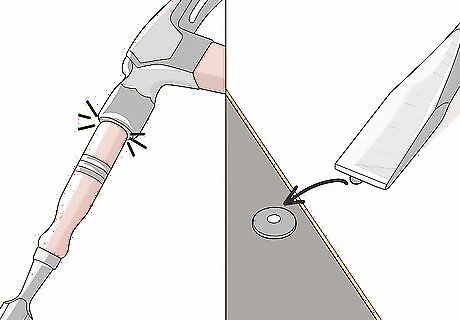

Use a punch to put a divot in the head of the rivet. Take a pin, center, or prick punch and hold it against the top of the rivet. Using your hammer, strike the end of the punch to create a small dent in the head of the rivet. Note: You may need to strike the punch more than once to create a deep enough divot for your drill bit to grip onto. Be careful not to miss the end of the punch and strike your hand with the hammer. Some punches are spring-loaded and will punch the rivet on their own.

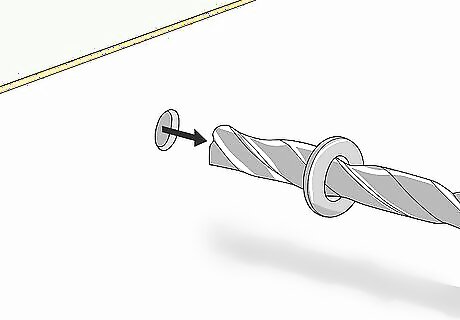

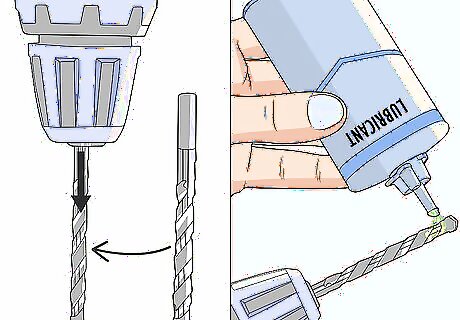

Attach a drill bit that fits neatly into the divot. Find a bit that fits into the divot and is long enough to penetrate all the way through the rivet. Tighten the chuck so that the bit is tight and secure. The end of the bit should be thin enough to fit snugly into the divot created by the punch so it can grip it. The drill bit should be the same size as the rivet or smaller. For example, for a ⁄4 inch (0.64 cm) rivet, use a ⁄4 inch (0.64 cm) or a ⁄16 inch (0.48 cm) drill bit.

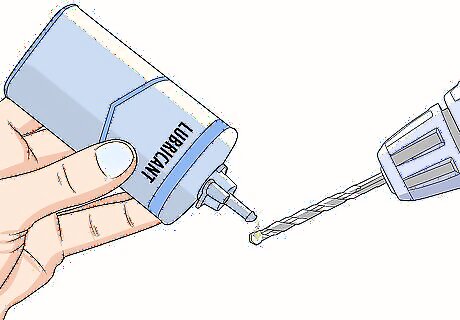

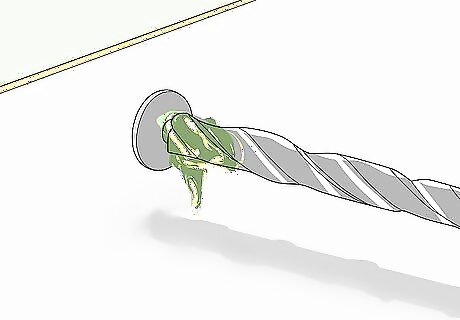

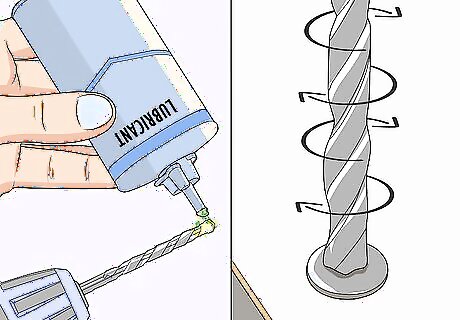

Add some lubricant to the end of the drill bit. Drilling the rivet will create lots of friction and heat. To help the bit pierce through the rivet without overheating or getting damaged, add a few drops of cutting fluid, or lubricant, to the end of it. Use your fingers to spread the lubricant all over the end of the drill bit. You can find drilling lubricant at hardware stores or online.

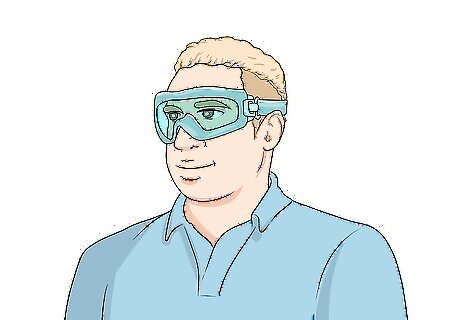

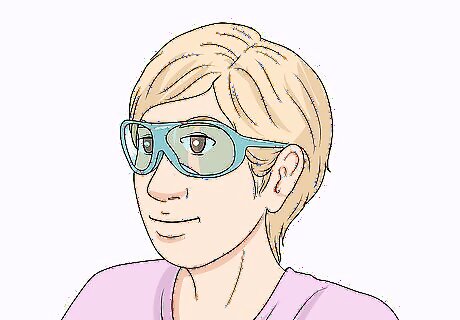

Put on safety glasses before you start drilling. Rivets are made of metal and they’re often fastened to metal surfaces. Drilling against metal can create sparks or cause fragments to fly off, which could possibly injure your eyes. Before you start to drill, put on a pair of safety glasses that fit securely. Standard eyeglasses are not adequate protection. Be sure to wear safety glasses that are rated for drilling or cutting metal.

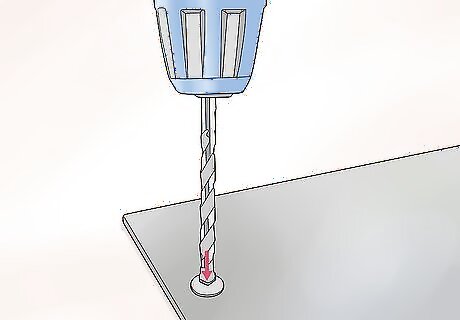

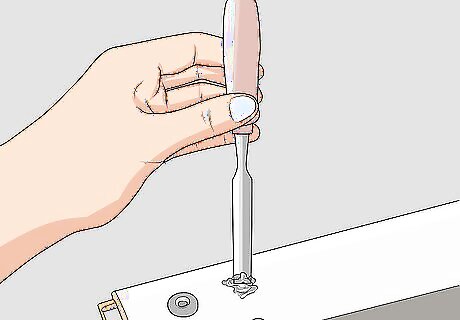

Place the drill bit against the divot in the center of the rivet. The bit should fit into the divot, but you’ll need to apply pressure to hold the end of the bit against the rivet. Be careful not to apply too much pressure or it could cause the drill to slip and the bit to scratch the surface holding the rivet. Keep one hand on the handle of the drill to apply pressure and another to hold the drill in place.

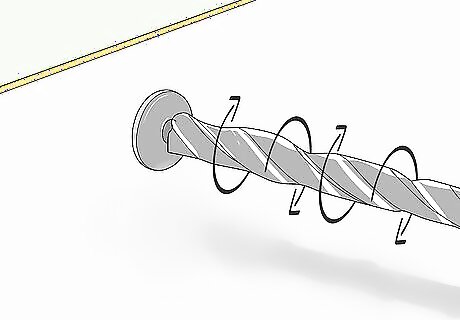

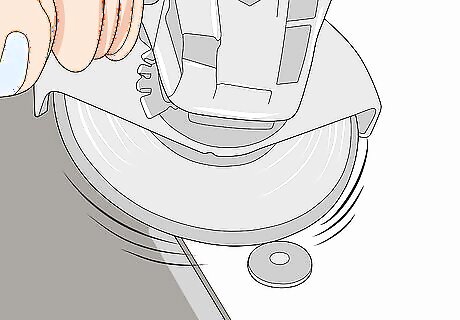

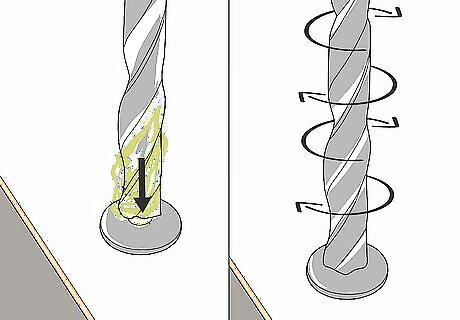

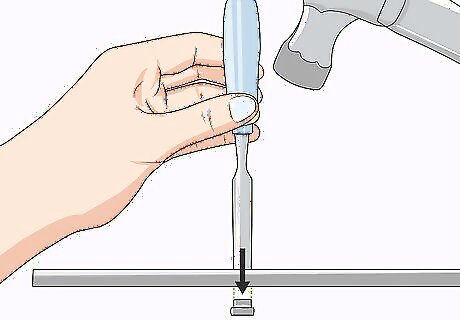

Maintain a low but steady speed while you drill through the rivet. Boring through metal rivets is done with pressure rather than speed. Start the drill slowly and maintain a steady pace as you hold the drill against the rivet and apply firm pressure. Don’t press too hard against the rivet or the drill bit could slip or possibly bend.Tip: Apply more lubricant if the rivet starts to smoke or the drill bit is having trouble picking up speed.

Drive the rivet through the surface with the drill. Continue to maintain pressure and a steady rate of speed as you drill through the rivet. Eventually, the rivet will be pushed all the way through the hole. Don’t stop drilling until the rivet is completely removed from the surface.

Grinding the Rivet Off

Put on safety glasses to protect your eyes. Grinding metal can send sparks and shards of metal flying. It’s very important that you strap on a pair of strong safety glasses before you start cutting metal rivets. Make sure the safety glasses are rated for metal work.

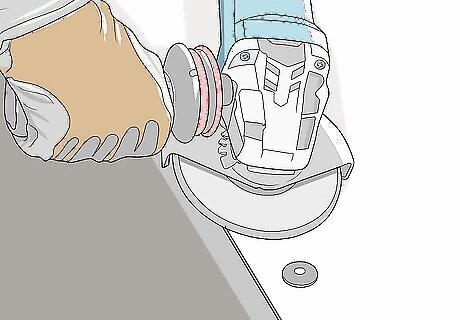

Hold the grinding wheel parallel to the surface with the rivet. Approach the head of the rivet with the wheel of the grinder as close to the point where the head of the rivet connects with the surface. Hold the grinder in a steady and fixed position to avoid scratching the surface.Warning: Do not try to wedge the wheel of the grinder beneath the head of the rivet before you start it. It will break the wheel and possibly send shards of it flying in the air, which could injure somebody.

Start the wheel and place the grinder against the head of the rivet. Bring the grinder wheel up to speed and slowly move it into a position parallel with the surface until you make contact with the head of the rivet. Slowly move the grinder as it cuts through the metal rivet until you remove the exposed head. If you feel resistance as you move, hold the grinder in place to allow it to finish cutting through the metal before you continue cutting through the rivet.

Punch a small dent into the top of the rivet. Once you’ve removed as much of the rivet head as possible, take a pin, prick, or center punch and place it in the middle of the rivet. Use your hammer to knock a dent into the center so your drill can grip the metal to penetrate it. Make sure you knock a good divot into the metal. You may need to hammer the punch a few times to make a deep enough dent.

Lubricate your drill bit and drill a hole through the rivet. Take a drill bit the size of the divot made by the punch to drill a pilot hole that will guide your larger bit. Drill the smaller bit all the way through the rivet. Drill at a steady speed and maintain pressure against the drill to pierce through the rivet. Look for cutting fluid lubricant at your local hardware store or online.

Change the drill bit to one the same size as the rivet and lubricate it. Once you’ve bored a pilot hole with the smaller drill bit, change it out for a bit just under the same size as the rivet. This bit will be thicker than the bit you used to drill a pilot hole. Add a few drops of lubricant to the end of the bit. Make sure the bit is fitted into the drill securely so it doesn’t come loose when you’re boring through the metal. Spread the lubricant around the end of the bit with your fingers to ensure even coverage.

Place the drill bit into the pilot hole and drill through the rivet to push it out. Fit the end of the bit into the divot and pilot hole you just made. It should fit neatly into the hole. Apply firm pressure and drill at a steady pace to bore through the rivet and push it all the way through. Maintain steady pressure as you drill. Be sure not to press too hard or the bit could slip and scratch the surface.

Using a Hammer and Chisel

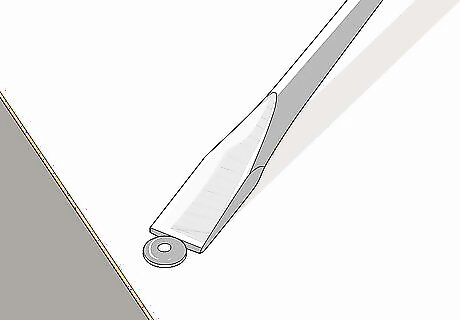

Wedge the thin end of the chisel beneath the head of the rivet. To gain some leverage to help knock off the head of the rivet, take a chisel and place the sharp end into the edge where the head of the rivet and the surface connect. Wiggle the chisel a little bit to really wedge it into place.

Break off the head of the rivet by hitting the chisel with a hammer. Use your hammer and knock against the dull or wide end of the chisel to knock off the head of the chisel. It will probably take several strikes to remove the head. Be careful not to slip and hit your hand with your hammer.Tip: The head of the rivet may not break off evenly. Use your hammer and chisel to chip off any pieces of the head that remain.

Place the chisel against the top of the rivet. Once the head of the rivet has been removed, you can work to punch the rivet through the surface. Place the thin end of the chisel against the rivet and hold it securely in place. It may help to knock a few dents into the rivet to help hold the chisel in place. If the rivet is small, use a punch to hammer it through the surface.

Hammer the chisel until the rivet is pushed through the surface. Strike the thick or dull end of the chisel with controlled, firm strikes with your hammer. Continue to hammer the chisel until the rivet is pushed through the surface. Don’t rush or try to hammer the rivet quickly. You’ll be much more likely to slip and injure yourself.

Comments

0 comment