views

Preparing to Oil the Machine

Follow the instructional manual. Each sewing machine brand is different, so it’s a good idea to check the manual that came with your sewing machine for directions on how to clean and oil it. Ensuring your sewing machine is oiled will keep the mechanics lubricated and running smoothly. Some manufacturers recommend cleaning the machine after every 10 hours you use it. Clean it when you see lint starting to gather. Some older machines mark the spots where you should drop oil in red. Others tell you where to drop it using pictures to guide you. If you don’t have a copy of the instructional manual, you should be able to get one on the manufacturer’s website. You might even be able to download it. If that doesn’t work, call the manufacturer and ask for one. You will be asked the machine name, model, and serial number most likely. You could also ask a local dealer. Some machines do not need to be oiled. They are self-lubricating. Such a machine will still need to be maintained, but if it says not to oil it at home, don’t.

Go slowly. You want to make sure that you don’t use too much oil. It’s a good idea to use a little bit of oil, and see how it works. Then use more. Place a piece of newspaper under the machine while you work. Oil small areas at a time. You should take apart small areas of the machine piece-by-piece to oil them. Study the instructional manual drawings first so that you understand the function and name of each part. Do not put oil on the needle, bobbin, presser foot, or plate, as it will stain your fabric. Disassemble the parts following the instructions in your manual. You will want to follow a process of cleaning the piece, brushing it out, and then lubricating each area. After you finish with each area of the sewing machine, you will want to put it back together, and then move on to the next part. Replace needles frequently. You will probably want to do this with each new project.

Prepare the machine for cleaning. You should clean the machine before you oil it. First, turn off the machine and unplug it. Remove all of the extra pieces of the machine that will get in the way of a thorough cleaning. For example, remove thread, bobbin cases, plates, and the presser foot. Remove the stitch plate. If your machine has a bobbin hook, you should remove it because lint could be collected there. Remove the machine’s needle for safety purposes.

Cleaning the Machine

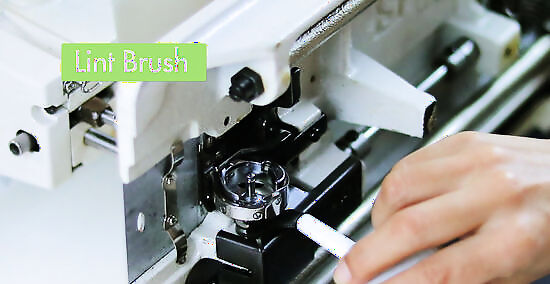

Take a small, stiff lint brush. You should be able to brush away the lint with the stiff lint brush. Brush away the lint that you can. Sometimes these small lint brushes and other cleaning materials will come with the sewing machine. To reach pieces of lint that are hard to sweep away because they are compacted, try using tweezers to remove them. It's essential that you thoroughly clean your machine before you apply the oil. Try using a soft cloth to wipe away any lint or residue on the bobbin hook. Some people also use clean mascara brushes or pipe cleaners for this process.

Use compressed air. You could clean parts of the machine with a can of compressed air. There are some cautions necessary with using compressed air, though. The problem with canned air is that it could blow lint deeper in the machine. To reduce this problem, hold the nozzle at least 4 inches (10.2 cm) away from the machine part, and spray air at an angle into the machine so it blows the lint out of the machine instead of into it. Use the air to clean the bobbin case area and the bobbin case itself. This is the area where the bobbin loads up. Stray dust should fall out.Use the air to clean the bobbin case also. Clean under the needle plate also. You will have to unscrew the needle plate. Remove the plate. You will see dust inside of it. Spray the area with the compressed air. Clean any other parts as instructed by your sewing machine manual.

Oiling the Machine

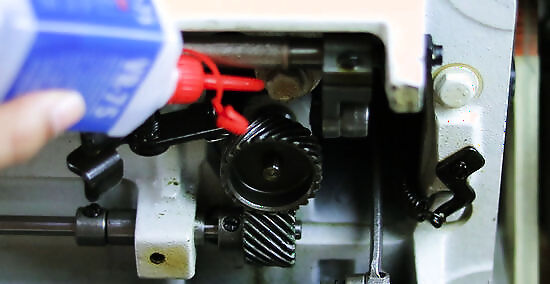

Buy sewing machine oil. You cannot use car oil. You need to buy oil that is specifically for sewing machines. Sewing machine oil is clear and comes in a small bottle. Your sewing machine may have come with a bottle of oil when you purchased it from the dealer or store. You can find this oil in sewing and fabric shops. This cannot be said enough. You cannot use any other oil than the oil recommended in your owner’s manual. Household oil or WD-40 will not work. Sewing machine oil is of different consistency than oil you’d put in a car. It’s clear and lighter.

Put drops of oil into sewing machine parts. You should only need a small amount of oil. Your owner’s manual will tell you where to drop it in the machine. It only takes a couple of drops. Generally, you will be told to squeeze a few drops of oil on the housing unit that the bobbin case sits in. Most machines want you to oil the shuttle hook (which is the thing that spins inside the bobbin casing). Often you will be told to drop oil inside the hook race and the housing of the sewing machine. That’s the silver ring that the bobbin hook fits into. Your machine will perform better and be quieter if you drop oil here because the two pieces rub together. You may also be instructed to put a drop of oil on the outer ring of the bobbin hook. This is where it slides along the hook race.

Wipe away excess oil. Try to avoid getting any oil on parts of your sewing machine that will touch the fabric. However, if you do see any oil on the presser foot or plate, or on the needle or bobbin, use a cloth to wipe it away. Otherwise, that oil could end up on your fabric and thread. If you use too much oil, you can run muslin through the machine, and then wipe the exterior of the machine. Use a damp, soapy towel. Let it sit. That way the oil will collect. Then, do it again. You might need to do this a few times over the subsequent days until all of the extra oil is not in the machine. Test the machine. Before you start sewing a new project, make a few stitches on a piece of fabric you don’t care about. You want to see if any excess oil remains. Screw the needle plate back into the sewing machine.

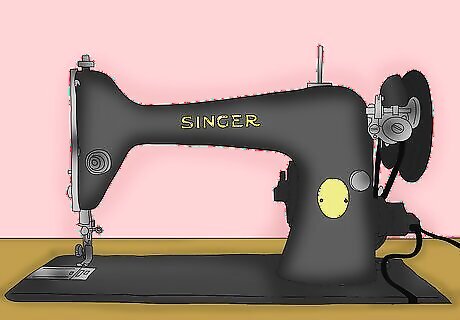

Oil a Singer sewing machine. Remove the needle plate. Turn the handwheel towards yourself until the needle is fully raised and open the hinged front cover. Unscrew the needle plate screws. A screw driver will come with the machine. Clean the feed dog. Remove the bobbin. Use the brush supplied to clean the area. Remove the bobbin case. Snap the two hook retaining arms outwards. Remove the hook cover and the hook. Clean with a soft cloth. Lubricate the points in the instructional manual with 1-2 drops of sewing machine oil. Turn the handwheel until the hook race is in the left position. Replace the hook. Replace the hook cover, and snap back the hook retaining arms. Insert the bobbin case and bobbin and replace the stitch plate.

Comments

0 comment