views

Making Stained Glass by Hand

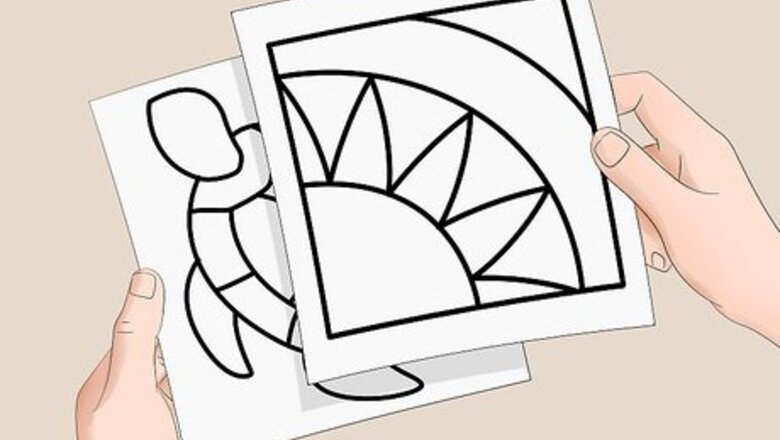

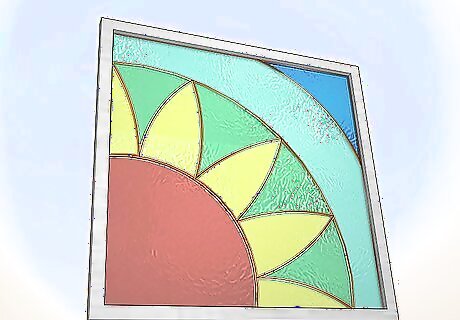

Pick a beginner-friendly pattern. Start with a smaller, simpler pattern that doesn't require too many parts. Look for free patterns online or create a pattern based on something that inspired you, like a natural object or a cathedral’s stained glass window. Look for inspiration in books and nature. A simple flower is a good choice for a beginner.

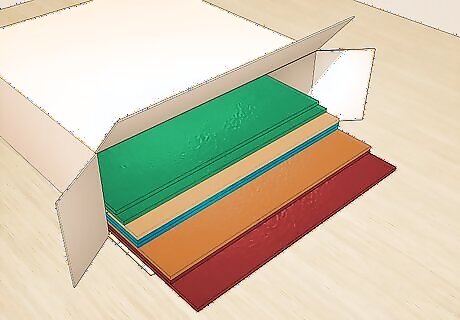

Purchase pre-stained glass sheets for an authentic project. Go to a shop specific to stained glass or to a larger hobby and craft store to find the stained glass for your project. Choose from the two main types of colored sheet glass: cathedral glass, which is clear colored glass, and opalescent glass, which incorporates white or opal glass into the color mix. Keep in mind that opalescent glass tends to require more pressure to cut through because the opal of the glass creates a higher density than cathedral glass. Pre-colored stained glass comes in large sheets. The smallest sheet is approximately 1 by 1 feet (30 cm × 30 cm), with the largest being four times that size. Buy enough glass for the size of your project, but keep in mind that about a quarter of what you buy will not be utilized after trimming. You can combine opalescent and cathedral glass in your project if you want an interesting mix of clear and opaque. There is also streaky glass, which tends to be cathedral glass with streaks of opal mixed in. EXPERT TIP Douglass Brown Douglass Brown Glassblowing Expert Douglass Brown is a Glassblowing Expert based in Half Moon Bay, California. He has over 25 years of experience as a glass artist, and is the owner and operator of 2 glass blowing studios in the San Francisco Bay Area, Half Moon Bay Art Glass and Mare Island Art Glass. Douglass believes in sharing hot glass experiences with anyone who wants to learn about the processes of blowing and sculpting glass. When not teaching, Douglass creates glass art that is a mix of his takes on nature and functional glassware. He has also created the Glass Troubadours, which is a mobile glass blowing studio that hosts parties, events, and visits craft shows. Douglass Brown Douglass Brown Glassblowing Expert Cathedral glass is a type of glass that is relatively thin, measuring no more than 5mm. Its thinness makes it easier to cut through, requiring less pressure. The name is derived from the stained glass windows featured in medieval European cathedrals from the 10th century onwards.

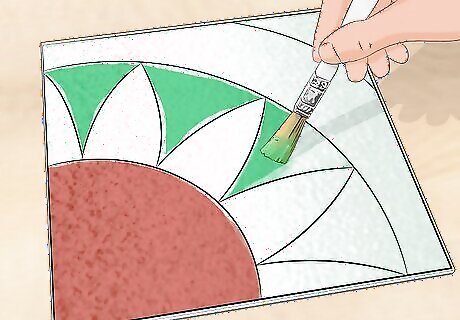

Color your own glass sheets as an alternative. If you’d prefer to stain your own glass rather than buy pre-stained glass, start with any piece of plain glass you have on hand. Apply a thick layer of your preferred color of glass paint over the entire panel with glass-specific paintbrushes. After you finish applying your paint, let your stained glass dry completely before touching it or cutting the pieces apart. Alternatively, you can mix a few drops of regular acrylic paint into 3 tablespoons (44 mL) of clear school glue. Using glass paints and glue-diluted acrylic paints allows for the colors on your glass to appear transparent, just like traditional stained glass. If you get any bubbles in your paint, pop them with a toothpick or needle. If you’re not sure where to find glass, try searching at a junkyard, asking a glass shop to make a sheet to fit your window, or removing the glass panel from an unused picture frame. Keep in mind that this is technically faux stained glass. Authentic, pre-colored stained glass is made by mixing colored minerals into the glass before it solidifies.

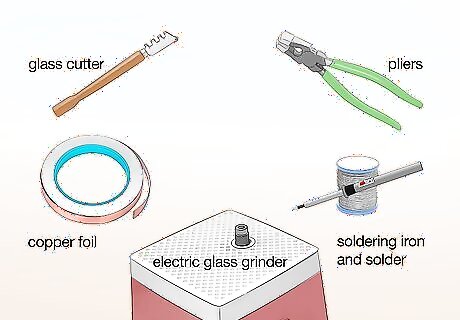

Gather your equipment. Stained glass requires specific equipment like glass cutters, special pliers, copper foil, soldering irons, and grinders. Look for specialty equipment online, at hobby or craft stores, or at a stained glass supply shop. Glass cutter: The hand cutter has the best flexibility and accuracy in template cutting, while the pencil-style cutter is great for beginners because it has consistent pressure and control. The Pistol grip is great for cutting thick glass. Pliers: Purchase Grozer pliers for breaking glass and nipping off edges, as well as running pliers for snapping long cuts in the glass. Copper foil: Find copper foil with the same width as your glass. Soldering iron and solder: Solder is a mixture of tin and lead. The higher the tin content, the lower the melting point, which means it will flow more quickly and have a more silvery finish. You'll need a soldering iron designed for stained glass projects and with a minimum of 75 watts. The irons come with different-sized tips, depending on your project. Grinder: if you don't have access to a grinder, you can use a carborundum stone to grind down the edges of your glass after cutting. If you can get a grinder, the Electric Glass Grinder is great for dealing with sharp edges quickly.

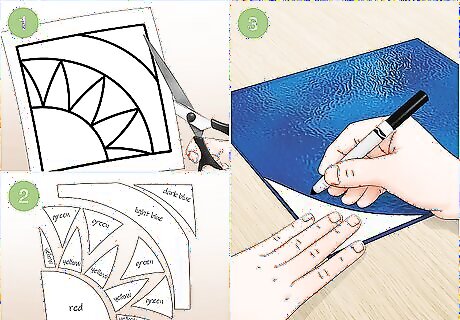

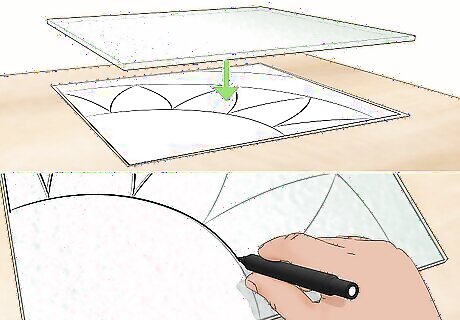

Make your template on a piece of paper. Draw, copy, or print out your pattern on a piece of graph paper. Cut the pattern into separate pieces and label them by color and grain direction. Place the pattern pieces under each piece of glass and trace the outline with a thin permanent marker. Leave a centimeter or less of room for the thickness of the copper foil between the pieces. Use either a specialty black pen or a permanent marker to mark the glass. If you have access to a lightbox, this can be incredibly helpful for tracing the pattern on the glass. EXPERT TIP Douglass Brown Douglass Brown Glassblowing Expert Douglass Brown is a Glassblowing Expert based in Half Moon Bay, California. He has over 25 years of experience as a glass artist, and is the owner and operator of 2 glass blowing studios in the San Francisco Bay Area, Half Moon Bay Art Glass and Mare Island Art Glass. Douglass believes in sharing hot glass experiences with anyone who wants to learn about the processes of blowing and sculpting glass. When not teaching, Douglass creates glass art that is a mix of his takes on nature and functional glassware. He has also created the Glass Troubadours, which is a mobile glass blowing studio that hosts parties, events, and visits craft shows. Douglass Brown Douglass Brown Glassblowing Expert Stained glass is a beautiful and enduring form of art that demands exceptional skill and expertise from glass artists. It has been used for centuries to create intricate designs in churches' windows and other significant religious buildings.

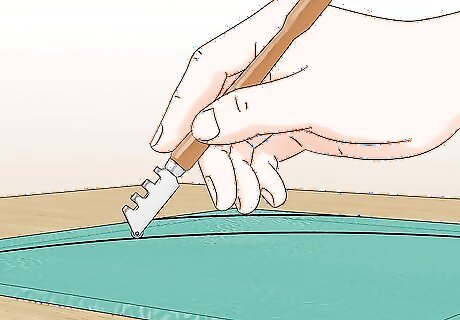

Score your glass. Put on protective goggles, cut-resistant gloves, and a protective face mask. Hold the glass cutter between your thumb and your forefinger with the tip pressed between your forefinger and your middle finger. Press the cutter into the glass gently, using a cork-backed steel ruler to cut straight. Begin at a point away from your body and begin scraping inward. Make sure that you're applying the right amount of pressure. You should hear a nice, clear "zzzzip" as you score. If you apply too little pressure, the break will not follow the score line. Too much pressure may cause the glass to crack. Move your pattern around, rotating the glass as necessary. Make sure that the scoreline goes from edge to edge. If your glass isn’t scoring correctly, make sure you’re standing to get better reach for long scores. Try a high-quality glass cutter with a carbide head—the oil lubrication is very helpful. Make sure to apply even pressure throughout your scoring and listen for a zipping sound as you score. If you're using opalescent glass, apply a bit more pressure than you would with cathedral glass.

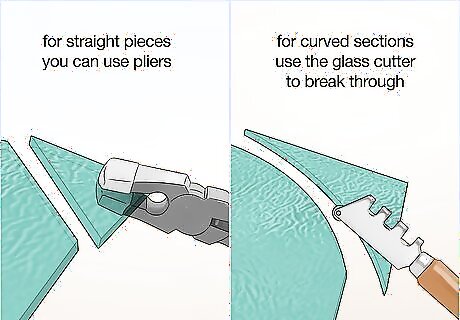

Cut your glass along the scored line. For straight pieces, as soon as you see a line forming, place pliers in the crack and squeeze to separate the piece. You can also hold the glass on either side of the break and snap it apart with your hands. For curved sections, use the glass cutter to break through the scoring. Don't worry if the piece breaks off slightly jagged; you can remove edges later, as long as you keep your curves gentle. If you're cutting deep curves, make a series of shallow curves so the glass won't break on its own. Always wear a grinding mask or other protective mask and goggles while cutting or grinding glass.

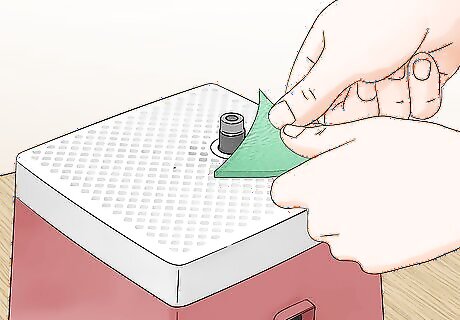

Grind the edges. Use a grinder to sand down the sharp edges and smooth everything out. Grind away gently and patiently to avoid chipping any of the pieces. As you grind each piece, check that it still fits the original pattern template. When you've finished grinding and fitting the pieces together, it's also a good idea to build a frame around them. This way, the pieces won't slip when you're foiling the glass. Regular sandpaper will also remove sharp edges if a grinder isn’t available. Wear glass-proof gloves to avoid cuts and a mask and goggles to avoid glass settling in your lungs or eyes.

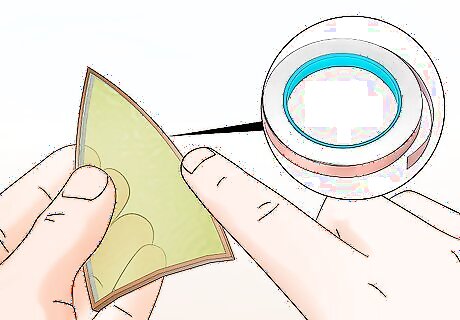

Foil the glass. Peel off the protective backing on ⁄32 inch (5.6 mm) copper foil tape. Center your glass on the tape and press it securely along all the cut edges. Press the foil down hard with a tongue depressor or other firm instrument, so it adheres to the glass. Make sure that the tape is very securely and evenly adhered. If a section gets bunched up, tear it off and start again. Make sure the foil is centered. Otherwise, it can look a little messy at the end. Centering can be done by hand or with a table foiler.

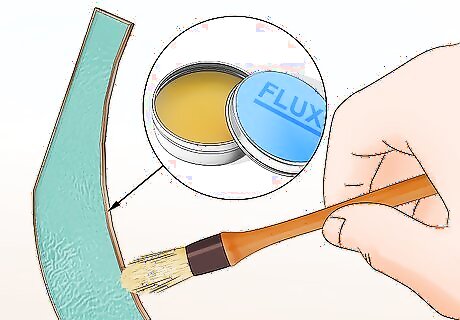

Apply flux to prepare your glass pieces for soldering. Brush a thin layer of flux onto each copper-foiled edge of your glass pieces. Flux cleans the metal so that the solder can flow smoothly and bond with the copper foil. This bonding will enable your glass pieces to better fit and stick together. Liquid or paste flux is recommended for most stained glass products, like the Ruby Fluid liquid flux. Other fluxes come in powder form and must be mixed with water before use.

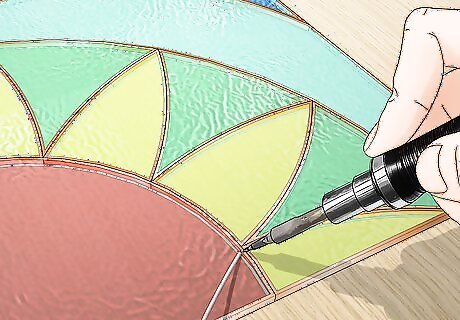

Solder the glass together. Before soldering the glass, put on personal protective equipment like a long-sleeve cotton shirt, closed-toe shoes, and safety goggles. Melt a small blob of solder onto the edge of each glass piece and fit all the pieces together—this is called “tacking.” Then, add a new lawyer of flux to each of the seams. Apply a thin, flat amount of solder on top of the flux. Make sure that you completely coat all of the copper foil. Finally, apply a new layer of flux to the tinned seams, then melt a larger amount of solder onto the seams. Run your soldering iron back and forth over to create a melted seam of solder. Once a section is completely melted, lift the iron from your piece to create a smooth bead. EXPERT TIP Luke Smith, MFA Luke Smith, MFA wikiHow Staff Writer Luke Smith is a wikiHow Staff Writer. He's worked for literary agents, publishing houses, and with many authors, and his writing has been featured in a number of literary magazines. Now, Luke writes for the content team at wikiHow and hopes to help readers expand both their skillsets and the bounds of their curiosity. Luke earned his MFA from the University of Montana. Luke Smith, MFA Luke Smith, MFA wikiHow Staff Writer "I think the Hakko FX-601 Soldering Iron is by far the best iron for beginners and more experienced crafters alike. It's got a long cord for easy handling, heats up quickly, and is buttery smooth to use."

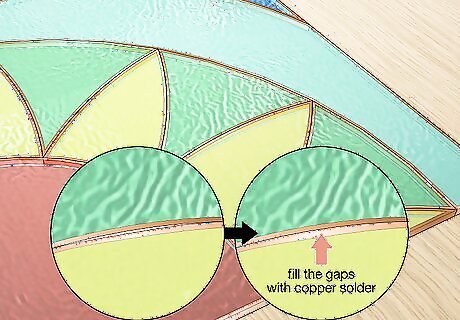

Troubleshoot gapping, scoring, or soldering issues with your glass. If you have any gaps between your glass pieces, fill them with copper solder and solder as you would normally. If your glass looks “charred” after soldering, you’re using the wrong type of flux. Look for a flux that’s good for higher temperatures. Use the right size soldering iron tip. Make sure that you know the width of the glass you're working with and have the tip and the copper spaced accordingly.

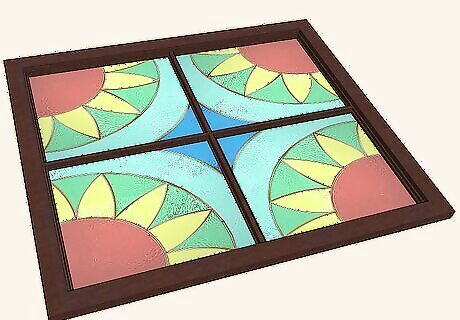

Build a wooden frame for your stained glass panel. Purchase four 6 ft (1.8 m) strips of oak framing stock. Measure your stained glass panel. Use a miter saw to cut two pieces of wood to the length of your panel and two to the width. Cut each oak piece at a 45º angle. Apply wood glue into every cut edge and connect the pieces together. Lay the frame flat to dry. Center a corner brace onto each corner. Use a pencil to mark where the screws will go. Put on protective goggles before using a drill to make pilot holes; use a drill bit that’s one size smaller than your screws, and don’t drill all the way through the wood. Then, drill your screws in. Slide your stained glass panel into the empty frame. Apply silicone caulk to the glass panel’s edges in order to adhere it to the frame. Alternatively, you can purchase oak frames that have grooves in the back to mount your stained glass piece into.

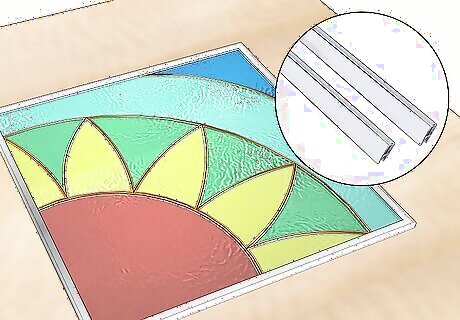

Create a came frame for your stained glass piece as an alternative. Cut lead or zinc came to fit each length of your stained glass piece. Fit the came around your design and solder it at the corners where the ends meet or where the came intersects with the outer perimeter. Cut off any excess and, if possible, attach hanging rings to the corners to help support the panel’s weight. Lead and zinc caming give stained glass a smoother and more consistent edge than wooden frames. Lead caming can be used on irregularly-shaped pieces, while zinc caming works best on straight edges or gently curves.

Install your stained glass in a pre-existing window frame, if desired. Place the panel against the empty window frame to make sure it fits—allow for about a ⁄8 inch (3.2 mm) gap around the glass. Cut some strips of cardboard to use as spacers between the glass panel and window frame. Wedge them into the gap to hold the stained glass in place while you apply the adhesive. Fill the gap between the window and frame with clear caulking. Use toilet paper to wipe off any excess caulk. Fold up cardboard scraps to make a “spring.” Use this “spring” as a spacer to hold the panel in place while the silicone cures for up to 24 hours. If necessary, use painter’s tape to hold the panel in place while the caulk dries.

Easy Painted Stained Glass

Outline your stained glass design onto a glass panel. Sketch your design ahead of time onto a piece of plain paper. Make sure that the paper is the same size as the glass you’ll be using. Lay the glass over your sketch and trace the outline of your design onto the glass with a black marker. Mix 1 tablespoon (15 mL) black acrylic paint into a 4 fluid ounces (120 mL) bottle of no-run school glue. Place the cap back on the glue and retrace the lines of your design. Let your outline dry overnight. Once the lines are completely dry, neaten them with a craft blade if necessary.

Use clear glue and acrylic paint to create your desired glass colors. Combine 3 tablespoons (44 mL) of clear school glue with a few drops of your chosen acrylic paint. Fill in each section of your design with the glue-paint mixture. Use thick layers of paint and go all the way up to the black lines. Allow your faux stained glass window to dry for several hours until it’s dry to the touch.

Comments

0 comment