views

Building the Supercritical Dryer

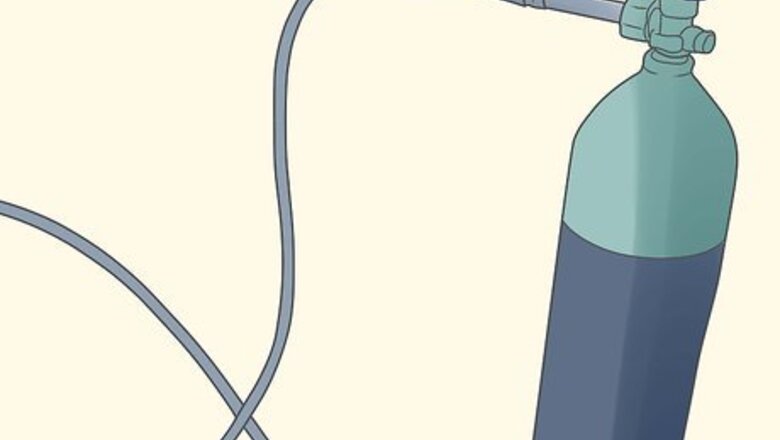

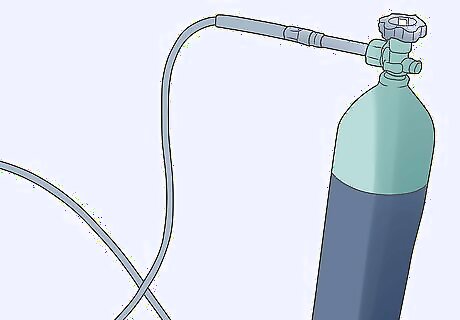

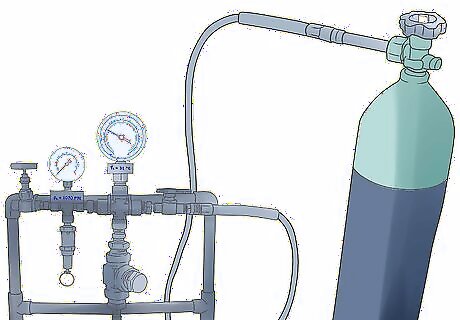

Obtain a 20 lb (9 kg) cylinder of carbon dioxide. Make sure that you get a siphon container, with a tube that extends from the bottom to the outside of the cylinder. This type of cylinder should allow you to get liquid carbon dioxide out of the container rather than merely gas.

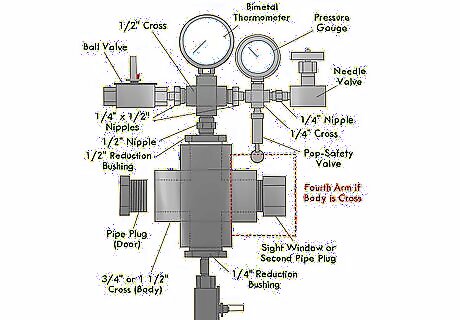

Take a look at the visual schematics. Instructions on how to assemble the supercritical dryer will be included here, but it is highly recommended that you take a look at the actual visual schematics provided by the aerogel website. These schematics can be viewed here: http://www.aerogel.org/wp-content/uploads/2009/02/manuclave-design2.jpg

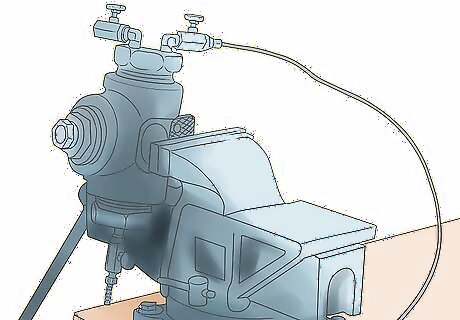

Attach stainless steel 316 or 304 pipe fittings and valves to a non-welding stainless steel pipe tee body. This pipe tee body should be 3/4 inch (1.9 cm). To the two sides of the tee body, you should attach the pipe plugs or door. You could install a sight window on one side instead of a second pipe plug, if desired. At the bottom of the tee body, you should connect a ball valve using a 1/4 inch (6.35 mm) reduction bushing. To the top of the body, screw on, in order: 1/2 inch (1.2 cm) reduction bushing, 1/2 inch (1.2 cm) nipple fitting, and 1/2 inch (1.2 cm) cross.

Finish assembling the top of the machine. The remainder of your valves and gauges will connect to this second cross pipe. Connect a Bimetal thermometer to the top of the cross pipe. To the left side, attach 1/4 inch by 1/2 inch (6.35 mm to 1.2 cm) nipple fitting. To date, attach a ball valve. To the right side, attach another 1/4 inch by 1/2 inch (6.35 mm to 1.2 cm) nipple fitting. To date, attach a 1/4 inch (6.35 mm) cross pipe with a pressure gauge fixed to the top and a pop-safety valve fixed to the bottom. On the open side arm of the smaller cross pipe, attach another 1/4 inch (6.35 mm) nipple fitting and a needle valve.

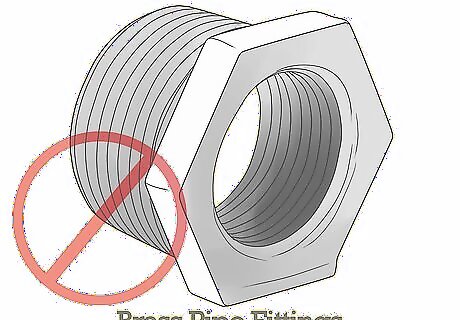

Know what you can and cannot use. Stainless steel is preferable since it is clean and strong. You can have gauges with brass threads and valves with carbon steel bodies. Do not use pipe fittings made of brass or carbon steels, and do not use any part rated for lower than 2000 psi.

Connect the carbon dioxide tank to the supercritical dryer. You will need to securely connect the tank to the dryer so that the liquid carbon dioxide can easily flow into the dryer. It is recommended that you look at the official schematics, found here: http://www.aerogel.org/wp-content/uploads/2009/02/gastank-1.jpg Connect to the carbon dioxide tank, in this order: CGA320 male thread, Teflon gasket, CGA inlet nipple, CGA inlet nut, 1/4 inch (6.35 mm) NPT female quick disconnect socket, 1/4 inch (6.35 mm) NPT male quick-disconnect plug, and a braided high-pressure hose, rigid 1/4 inch (6.35 mm) NPT, with female fittings. To the other side of the hose, attach in this order: 1/4 inch (6.35 mm) NPT male quick disconnect plug and 1/4 inch (6.35 mm) NPT male quick disconnect socket. Attach the final socket to the intake ball valve of the manuclave or dryer. With this, you should be ready to go.

Preparing Silica Aerogel

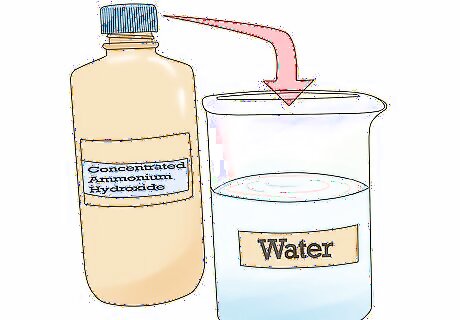

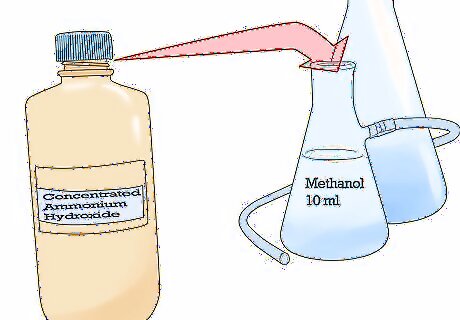

Dilute concentrated ammonium hydroxide. Combine 4.86 g or 5.4 ml concentrated ammonium hydroxide with 1000 ml of water in a glass or plastic bottle. This bottle should be labeled as "ammonium hydroxide stock solution." You can store it sealed and at room temperature to be reused at a later date.

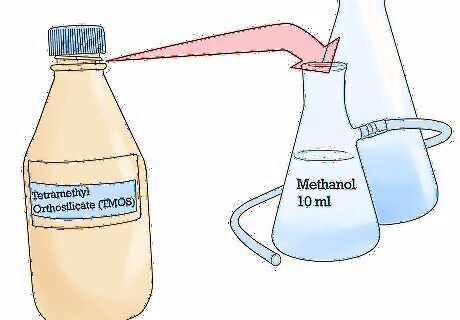

Mix the TMOS and methanol. Combine 10.2 g or 10 ml tetramethyl orthosilicate (TMOS) with 7.82 g or 10 ml methanol in a glass beaker. Stir until mixed. This should be labeled as "alkoxide solution" or "solution A." Note that TMOS can be very difficult to purchase since many chemical suppliers are hesitant to sell chemicals to individuals. Even so, you must make sure that you obtain the TMOS from a reliable source so that there are no dangerous impurities in it.

Mix the ammonium hydroxide solution with methanol. Combine 5 g or 5 ml of the stock solution previously prepared with 7.92 g or 10 ml of methanol in another glass beaker. Stir until well mixed. Label this beaker as "catalyst solution" or "solution B."

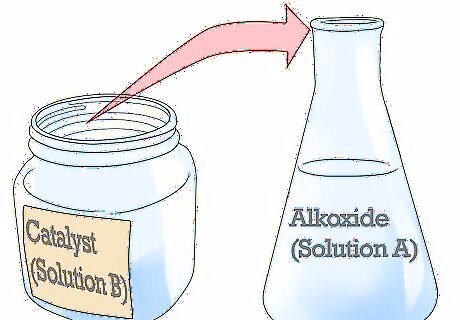

Pour the catalyst solution into the alkoxide solution. Carefully pour the catalyst (solution B) into the alkoxide (solution A) and stir with a glass stirring rod until completely combined. Note that the resulting solution is called the "soul."

Transfer the sol into molds. Line your molds with silicone-based baking paper before pouring the liquid sol into them. Let the sol sit until gel forms. This can take anywhere from 15 minutes to 1 hour. You could also pour the sol into syringes with no needles or tops. That way, you can remove the finished gel by pushing it out with the plunger. TMOS is the source of the silica in this method. The water allows the TMOS to polymerize, and the methanol lets both the water and TMOS enter into the same phase so that they can react. The ammonium hydroxide lets the reaction go faster.

Let the gel age. After the gel sets, place it under methanol and let it age for a full 24 hours, at minimum.

Diffuse the water out. Change the methanol out for fresh methanol, 200-proof ethanol, or acetone at least four times over the course of a week. This process draws the water out, leaving you with a pure methanol gel.

Dry the gel in your supercritical dryer. Place the gel in the supercritical dryer's compartment and heat the carbon dioxide through its critical point, 31.1 °C (88.0 °F) and 72.9 bars, to about 45 °C (113 °F) at a pressure of about 100 bars. Super critical drying causes the methanol to get drawn out of the gel. Depressurize the machine at a rate of about 7 bar h-1. When done, you should be left with a finished silica aerogel.

Alternate Drying Instructions – Subcritical Drying

Prepare the aerogel as usual. Prepare the silica aerogel as instructed previously, combining the same chemical ingredients to produce the "sol," the liquid state of the gel.

Purify the gel through solvent exchange as usual. Cover it in ethanol or acetone, changing the solution out four times over the course of a week.

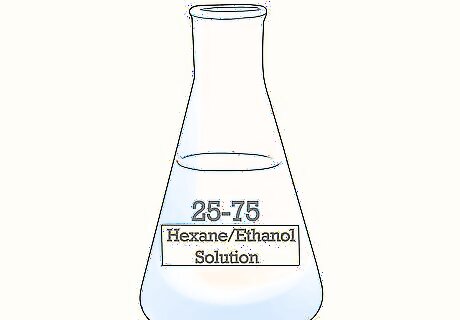

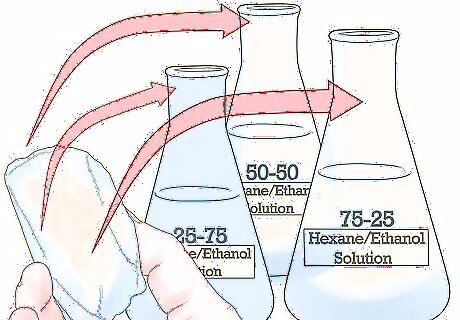

Prepare a hexane and ethanol solution. Mix one part hexane with three parts ethanol until you get a volume that is at least five times as great as the volume of gel currently being processed. Note that you could use acetone instead of ethanol, if desired. As an example, if you are processing 20 ml of aerogel, you should prepare a solution of 25 ml hexane and 75 ml acetone or ethanol. Label this as your 25-75 mixture.

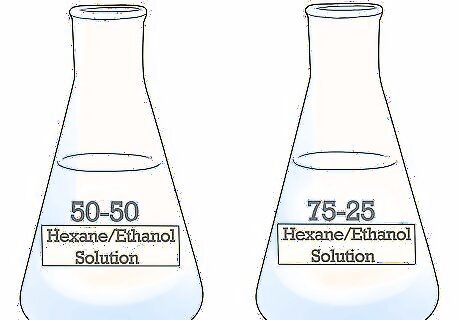

Prepare two additional solutions of hexane and ethanol. For the second, use equal amounts of both. For the third, use three parts hexane to on part ethanol. As before, acetone can be used instead of ethanol. Label the second solution as your 50-50 mixture and the third as your 75-25 mixture.

Soak the gel in all three mixtures. Let the gel soak in your 25-75 mixture for 12 to 48 hours. Afterward, let it soak in your 50-50 mixture for the same amount of time, finishing up by letting it soak in the 75-25 mixture for another 12 to 48 hours.

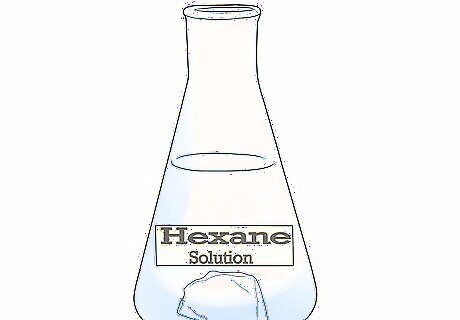

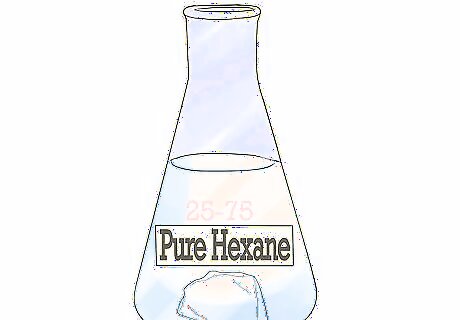

Let the gel soak in hexane. Change out the pure hexane three times over the course of 24 to 72 hours.

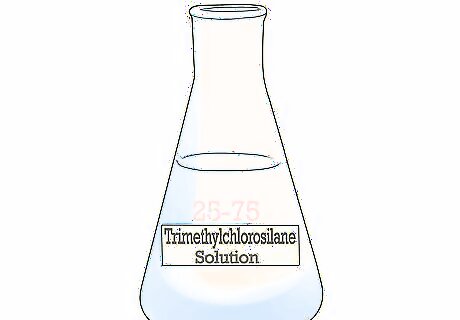

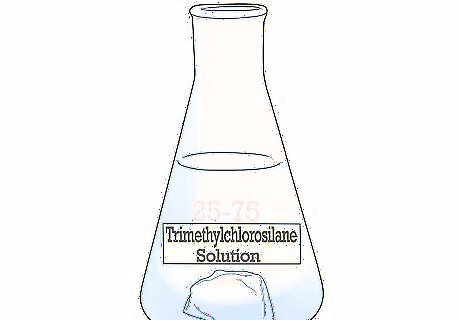

Prepare a trimethylsilyl chloride solution. Add TMCS to hexane so that 6 percent of the solution's weight is due to TMCS. Make enough so that you have roughly 15 times as much solution as you have gel. Label this as your TMCS solution.

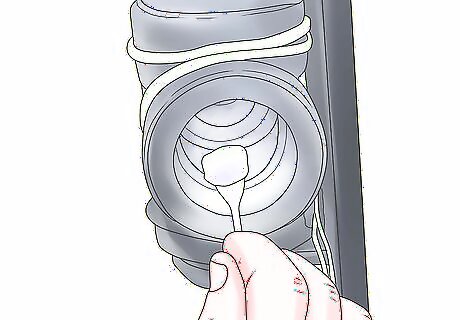

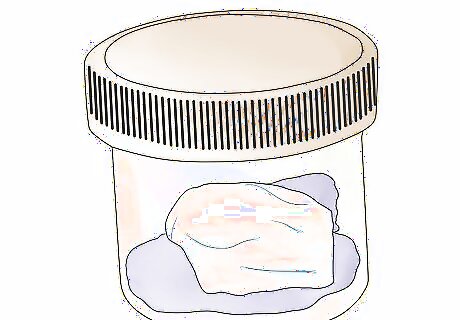

Soak the aerogel in the TMCS solution. Place the gel in a sealed, chemical-resistant container with a wide mouth. Add enough TMCS solution so that you have 5 to 10 times the volume of the gel. Seal the container. Lubricate the lid with silicone vacuum grease if using glass. Otherwise, the lid might get stuck.

Heat and cool the container. Heat the container for 12 to 24 hours at a steady 60 °C (140 °F), using a hot plate or oven. Let it cool to room temperature before exchanging the TMCS solution with fresh solution. Repeat this procedure twice more.

Let the cooled gel soak in pure hexane. Swap out the TMCS solution for pure hexane and allow the aerogel to soak in it for another 12 to 24 hours. Over the course of 24 to 72 hours, change out the hexane in the container for fresh hexane at least twice.

Subcritically dry the gel. Place the gel in a jar with a little hexane and secure the lid only halfway. Let the gel dry out for 1 to 2 days in this manner. At the conclusion of this step, your aerogel should be complete.

Comments

0 comment