views

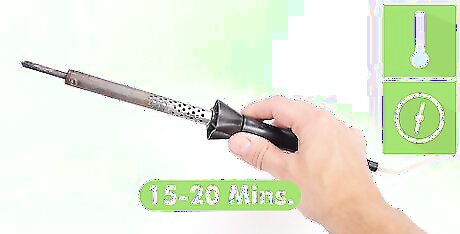

Cleaning the Tip

Let the iron cool before cleaning it. Turn off your solder iron and let it cool down for 15-20 minutes before cleaning the tip. This will allow you to clean the device as thoroughly as possible without risking burns. Clean the tip immediately after the solder iron to limit buildup over time. Place a sticky note near your workspace if you find yourself forgetting often to make cleaning the iron a priority.

Wipe the iron off with a damp, cellulose and sulfur-free sponge. Take a wet sponge and rub it over the top of the solder iron. Doing this first will take care of any mild buildup and help you discern in a safe way whether the tip is still too warm to touch with bare hands. Use sulfur-free sponges made specifically for soldering, as regular sponges will not remove the solder as efficiently.

Use dampened steel wool to get rid of surface stains or rust. If you do not regularly clean your solder iron, you may have more stubborn stains or discoloration. Take a steel wool pad and dampen it slightly, then scrub it over the iron's tip to remove rust and any other heavy staining. Steel wool is the only cleaning item safe to remove rust or stains with. Avoid sandpaper, which is too corrosive for solder iron tips.

Tinning the Iron

Wear eye protection while tinning the tip. After cleaning the tip, it is advised that you coat the tip in a thin, even layer of solder. This is called "tinning," and it helps protect the tip from rust or oxidization. That being said, many chemicals in solder are eye irritants. Solder has a tendency to "spit," or pop if you accidentally hit an air pocket, so keep safety goggles on at all times. Tin the solder iron after every use to prevent rusting. Make sure to wear eye protection at all times while using a hot solder iron. Although gloves are not required for tinning, it is suggested that you wash your hands with soap and water afterward.

Apply a small amount of fresh solder to the iron tip. Melt a small dot of solder over the tip in a thin coat. If applied evenly, this will keep the iron's heat flow in check when it is next used in addition to preventing rust accumulation.

Keep the solder in place with an alloy cleaner. After turning the solder iron off and letting it cool, apply a small layer of alloy cleaner over the tip with a microfiber cloth. This will prevent dust buildup over the solder and further diminish the chances of oxidization.

Maintaining a Solder Iron

Use high-quality solder. Although using cheap solder may seem cost-effective in the short term, it can cause damage over time. Impurities in your solder can cause buildup on the tip and inhibit its heat-transferring abilities. 60/40 or 50/50 solder is ideal, with the top number representing what percentage of tin is in the solder.

Remove debris buildup after every use. After soldering an item, turn the solder iron off and wait for it to cool. Then, remove the tip and tap the barrel to dislodge any debris. This will prevent buildup from clogging your solder iron over time and diminishing its efficiency.

Check the solder iron's cord for burns or cracks. A solder iron's cord is prone to damage because of the high heat the device is used under. If you notice any cord damage, hire a professional electrician to replace the cord. Solder irons with cord damage are not only inefficient but also dangerous to work with.

Wipe off the iron's tip between strokes. Cleaning the solder iron's tip while it is in use will result in better soldering work. Wipe a wet sponge across the solder iron's tip after each stroke to avoid buildup on the tip. When you're finished with your soldering job, you will have less to clean from the tip if you wipe the iron periodically while using it.

Comments

0 comment